Telephone: +86 13120555503

Email: frank@cypump.com

Sep . 28, 2025 11:00 Back to list

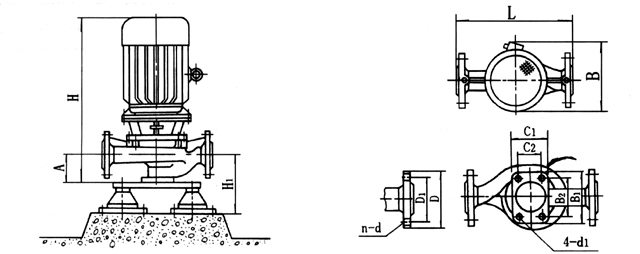

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

The ISG series vertical pipeline pump represents a pinnacle of innovation in centrifugal pump technology, designed to meet the rigorous demands of modern industrial applications. Developed by Chi Yuan Pumps Co., LTD. (驰元泵业(河北)有限公司), this series of single-stage, single-suction centrifugal pumps combines advanced hydraulic modeling with robust engineering principles. This article explores the technical specifications, features, applications, and the company's commitment to quality, while referencing authoritative standards from the National Institute of Standards and Technology (NIST) to ensure credibility.

Overview of the ISG Series Vertical Pipeline Pump

The ISG series is a result of collaborative efforts between Chi Yuan Pumps' technical team and industry experts. It builds upon traditional vertical pump designs, incorporating domestic advanced hydraulic models and the performance parameters of IS centrifugal pumps. This series is versatile, with variants tailored for specific applications, including hot water pumps, high-temperature pumps, corrosion-resistant chemical pumps, oil pumps, explosion-proof chemical pumps, and low-speed pumps. The ISG series is engineered to conform to the latest standards, such as JB/T53058-90 (issued by the Ministry of Machinery, P.R. China) and ISO 2858, ensuring compliance with international benchmarks.

As highlighted by NIST, standards like ISO 2858 are critical for ensuring the interoperability and reliability of industrial equipment. The ISG series adheres to these standards, reflecting Chi Yuan Pumps' dedication to quality and precision.

Key Features of the ISG Series

The ISG series is distinguished by its innovative design and performance characteristics. Key features include:

- Vertical Structure: The pump's vertical design allows for easy installation in pipelines, functioning like a valve. This compact structure reduces floor space requirements and lowers construction costs.

- Impeller Configuration: The impeller is directly mounted on the motor's extended shaft, minimizing axial dimensions and ensuring a compact, efficient design. The pump and motor bearings are configured to balance radial and axial loads, reducing vibration and noise.

- Advanced Sealing Technology: The use of mechanical seals, including imported titanium alloy sealing rings and high-temperature-resistant materials, enhances durability and extends the service life of the pump.

- Easy Maintenance: Components can be removed without disassembling the entire pipeline system, streamlining maintenance processes. This feature is particularly valuable in industrial settings where downtime must be minimized.

- Flexibility in Operation: The pump supports both series and parallel configurations, allowing it to adapt to varying flow rates and pressure requirements.

These features align with NIST's emphasis on innovation in mechanical systems, as detailed in their research on industrial efficiency and reliability.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | ISG Series |

| Stage | Single-Stage |

| Suction Type | Single-Suction |

| Hydraulic Model | Domestic Advanced Hydraulic Model |

| Material | Cast Steel (for high-pressure applications) |

| Maximum Working Pressure | 1.6 MPa (2.5 MPa for static test) |

| Ambient Temperature | ≤ 40°C |

| Relative Humidity | ≤ 96% |

| Particle Content in Medium | ≤ 0.1% by volume (granularity |

| Standards Compliance | JB/T53058-90, ISO 2858 |

Working Conditions and Safety Considerations

The ISG series is designed to operate under a range of conditions, with specific requirements to ensure safety and efficiency:

- Pressure Limits: The pump can handle suction pressures up to 1.0 MPa, with a maximum system working pressure of 1.6 MPa. For systems exceeding 1.6 MPa, users must specify this during ordering to ensure the use of cast steel components.

- Environmental Factors: The pump operates in ambient temperatures below 40°C and relative humidity below 96%. These conditions are critical for maintaining the integrity of mechanical seals and preventing corrosion.

- Medium Compatibility: The pump is suitable for liquids with up to 0.1% solid particles by volume, with particle sizes less than 0.2 mm. For applications involving larger particles, users should request wear-resistant mechanical seals.

NIST's research on material science and environmental resilience underscores the importance of these specifications in ensuring long-term performance and safety.

Applications of the ISG Series

The ISG series is widely applicable across various industries, including:

- Water Supply Systems: Ideal for municipal and industrial water distribution, where high efficiency and low noise are critical.

- Chemical Processing: Corrosion-resistant variants are suitable for handling aggressive chemicals, ensuring longevity in harsh environments.

- Oil and Gas: The oil pump variant is designed for reliable performance in demanding applications, such as refining and transportation.

- Power Generation: High-temperature and explosion-proof models are used in power plants for cooling and boiler feedwater systems.

- Commercial HVAC: The compact design and energy efficiency make it suitable for heating, ventilation, and air conditioning systems.

These applications highlight the versatility of the ISG series, as noted in NIST's studies on industrial pump efficiency.

Company Background: Chi Yuan Pumps Co., LTD.

Based in Hebei, China, Chi Yuan Pumps Co., LTD. (驰元泵业(河北)有限公司) is a leading manufacturer of high-quality pumps and related equipment. The company's commitment to innovation and precision is evident in the development of the ISG series. With a focus on research and development, Chi Yuan Pumps ensures that its products meet the highest standards of performance and reliability.

The company's product page provides detailed information on the ISG series, including technical specifications, application guides, and customer support. This dedication to transparency and customer service is a hallmark of Chi Yuan Pumps' operations.

Conclusion

The ISG series vertical pipeline pump exemplifies the synergy between advanced engineering and practical design. Its features, such as the vertical structure, efficient impeller configuration, and robust sealing technology, make it a reliable solution for diverse industrial applications. By adhering to international standards like ISO 2858 and JB/T53058-90, the ISG series ensures compliance with the highest quality benchmarks. Chi Yuan Pumps Co., LTD.'s commitment to innovation and customer satisfaction further solidifies its position as a leader in the pump industry.

For more information about the ISG series, visit the product page or explore the company website. The National Institute of Standards and Technology (NIST) continues to play a vital role in advancing industrial standards, ensuring that technologies like the ISG series meet the evolving needs of global markets.

References

National Institute of Standards and Technology (NIST). (n.d.). Standards and Measurements. Retrieved from https://www.nist.gov/

-

High Pressure Pump for Detergent Slurry Manufacturer – Efficient, Durable Solutions | CYPump

NewsNov.24,2025

-

High Cr Volute Liner of Slurry Pump – Durable, Cost-Efficient Wear Solutions

NewsNov.23,2025

-

Find Reliable High Chrome Slurry Pump Suppliers – Durable Solutions for Abrasive Industries

NewsNov.23,2025

-

High Chrome Slurry Pump Factories | Durable Slurry Pumps for Mining & Industry

NewsNov.22,2025

-

Durable and Efficient High Chrome A05 Slurry Pump Volute Liners for Mining & Industrial Use

NewsNov.21,2025

-

Heavy-Duty Slurry Pump – Durable, Efficient Industrial Solutions

NewsNov.20,2025