Luxembourgish

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Nov . 15, 2024 01:08 Back to list

china warman horizontal slurry pump

China Warman Horizontal Slurry Pump An Overview

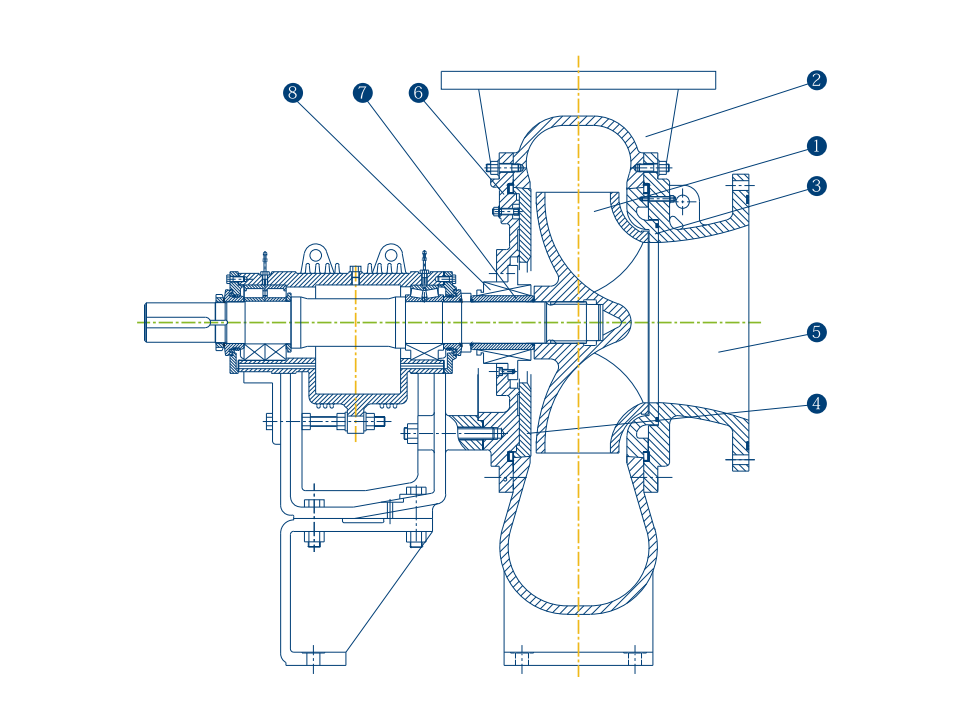

The mining, mineral processing, and industrial sectors have long depended on reliable pumping solutions for the transportation of abrasive and corrosive materials. Among the various types of pumps available, the Warman horizontal slurry pump stands out as a benchmark for efficiency, durability, and performance. Manufactured in China, the Warman series has carved a niche for itself in global markets due to its robust engineering and ability to handle the most challenging applications.

Understanding the Warman Horizontal Slurry Pump

The Warman horizontal slurry pump is specifically designed to transport slurries containing solid particles. Its horizontal orientation allows for a compact design, making it easier to integrate into existing systems. These pumps can efficiently handle a wide range of slurry types, including those found in the mining, coal, and chemical industries. They are particularly advantageous for applications involving high solids concentrations, as they can process heavier slurries that would be challenging for other pump types.

Key Features and Benefits

1. Durability and Wear Resistance One of the defining characteristics of the Warman slurry pump is its exceptional resistance to wear caused by abrasive materials. The pump casing and impellers are often made from high-chrome alloys or elastomers, which prolongs the life of the components and reduces maintenance costs.

2. Robust Design The pump features a simple yet effective design that includes a wide range of impeller options to optimize performance for different slurry types. The ability to customize the impeller based on the specific application further enhances efficiency.

3. Versatility Warman pumps are functional across various industries, from mining to wastewater treatment. Their adaptability makes them suitable for transporting not only slurries but also other viscous liquids, making them a valuable asset in diverse applications.

4. Ease of Maintenance The design of the Warman horizontal slurry pump facilitates straightforward maintenance. Features such as easy access to the pumping components reduce downtime and enable quick servicing, ensuring that operations remain uninterrupted.

5. High Efficiency With advancements in hydrodynamic design, Warman pumps are capable of moving slurries over long distances without significant energy loss. This high-efficiency performance translates to lower operational costs, making it an economical choice for industries requiring continuous pumping solutions.

china warman horizontal slurry pump

Applications in Industry

The Warman horizontal slurry pump has proven crucial in several key applications

- Mining and Mineral Processing In these industries, the pumps are used to transport tailings, concentrates, and other mineral slurries. Their ability to cope with high solids content makes them ideal for harsh mining environments.

- Coal Handling Warman pumps play an essential role in coal preparation and transportation, where the movement of slurries is integral to the process.

- Chemical Processing The robustness of the Warman pumps allows them to handle corrosive and abrasive chemicals, making them suitable for various chemical processing applications, including the transportation of slurries in the production of fertilizers and other chemicals.

Global Reach and Reputation

China's Warman horizontal slurry pumps have gained international recognition, being utilized across continents from North America to Australia. Their reputation for reliability and efficiency has made them a preferred choice among engineers and operators globally. The availability of service centers and spare parts ensures that customers receive continued support, enhancing their operational resilience.

Conclusion

In summary, the China Warman horizontal slurry pump represents a pinnacle of engineering in the industry of slurry transportation. With its durable design, high efficiency, and versatility across multiple applications, it meets the demands of modern industrial processes. As companies seek reliable solutions to manage slurry handling, the Warman series continues to lead the way, firmly establishing its position as a trusted partner for businesses worldwide. Embracing this technology not only enhances operational efficiency but also contributes to the sustainable management of resources in various sectors.

-

Heavy-Duty Mining Sludge Pumps - Wear-Resistant Slurry Handling

NewsAug.02,2025

-

Horizontal Split Case Pump with GPT-4 Turbo | High Efficiency

NewsAug.01,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

NewsAug.01,2025

-

Advanced Flue Gas Desulfurization Pump with GPT-4 Turbo | Durable & Efficient

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Hydraulic Design&Durable Construction

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Energy Efficient & Low Noise

NewsJul.31,2025