Kannada

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

ಡಿಸೆ . 12, 2024 14:58 Back to list

slurry pumps 4 hp

Understanding Slurry Pumps The 4 HP Solution

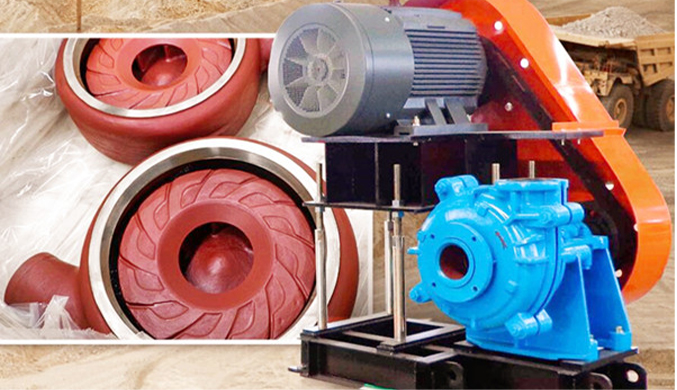

Slurry pumps are critical components in various industries, particularly in mining, construction, and wastewater treatment. Their primary function is to transport a mixture of liquids and solids, or slurry, from one point to another. The effectiveness of a slurry pump depends on several factors, including its design, materials, and the specific application it’s used for. One popular option among slurry pumps is the 4 horsepower (HP) model, which offers a balance of power, efficiency, and versatility.

What is a Slurry Pump?

A slurry pump is designed to handle a combination of water and solid particles. These pumps are built to work with materials that can be abrasive, corrosive, or highly viscous. Common applications include transporting ore pulp in mining operations, transferring sludge in wastewater treatment, and handling mixtures in construction processes. The design of slurry pumps typically features a robust construction to withstand wear and tear caused by abrasive particles.

The Role of 4 HP Slurry Pumps

4 HP slurry pumps are particularly sought after because they strike an ideal balance between power and portability. With four horsepower under the hood, these pumps can efficiently transport slurries without requiring extensive energy consumption. This makes them suitable for small to medium-sized operations where high output is necessary, but larger pumps would be overkill.

In mining applications, for instance, a 4 HP slurry pump can be used to transport sludges that contain waste material from extraction processes. These pumps can also be employed in smaller scale mining operations where the slurry volumes don't warrant larger pumps. Their compact size ensures they can fit into tight spaces, making them a favorite among contractors who need flexibility and maneuverability on the job site.

Key Features

1. Durability A significant feature of 4 HP slurry pumps is their robust construction. Typically made from materials such as stainless steel or high-chrome alloys, these pumps are designed to resist wear from abrasive solids, prolonging their operational lifespan.

2. Efficiency Modern 4 HP slurry pumps are engineered for energy efficiency. They are designed to displace substantial volumes of slurry while consuming relatively low amounts of power, making them cost-effective for long-term use.

slurry pumps 4 hp

3. Versatility These pumps can handle a wide variety of slurries, from relatively thin mixtures to those with a high concentration of solids. This versatility makes them suitable not only for mining but also for construction, agriculture, and industrial applications.

4. Ease of Maintenance Many manufacturers design their slurry pumps for ease of maintenance. The ability to clean and replace parts without disrupting the entire system enhances operational uptime and efficiency.

Applications

The applications for a 4 HP slurry pump are diverse

. Beyond mining, they can be used in- Construction Sites For transferring cement slurries and other mixed materials.

- Wastewater Treatment In the transportation of sludge to and from treatment facilities.

- Agricultural Settings For moving liquid fertilizers and other slurry-based products.

- Dredging Operations In the removal of sediment and debris from water bodies.

Conclusion

The 4 HP slurry pump serves as a highly effective solution for various applications requiring the movement of slurries. Its optimal power output makes it suitable for both large and small-scale operations, providing the efficiency and durability needed for a myriad of industrial tasks. Whether in mining, construction, or wastewater management, the versatile capabilities of a 4 HP slurry pump ensure that it remains a staple component across many sectors. As industries continue to evolve and demand more efficient solutions, the role of slurry pumps, particularly in the 4 HP category, will only grow in importance.

-

High-Performance Air Pumps for Sand & Gravel | Efficient Transport

NewsAug.03,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Energy Efficiency, Corrosion Resistance

NewsAug.03,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | Energy Efficiency&Compact Design

NewsAug.03,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Low Noise, Durable

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump- Chi Yuan Pumps Co., LTD.|High Efficiency&Compact Design

NewsAug.02,2025