Kannada

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

ನವೆಂ . 21, 2024 00:09 Back to list

oem rubber lined slurry pump manufacturers

The Importance of OEM Rubber Lined Slurry Pump Manufacturers

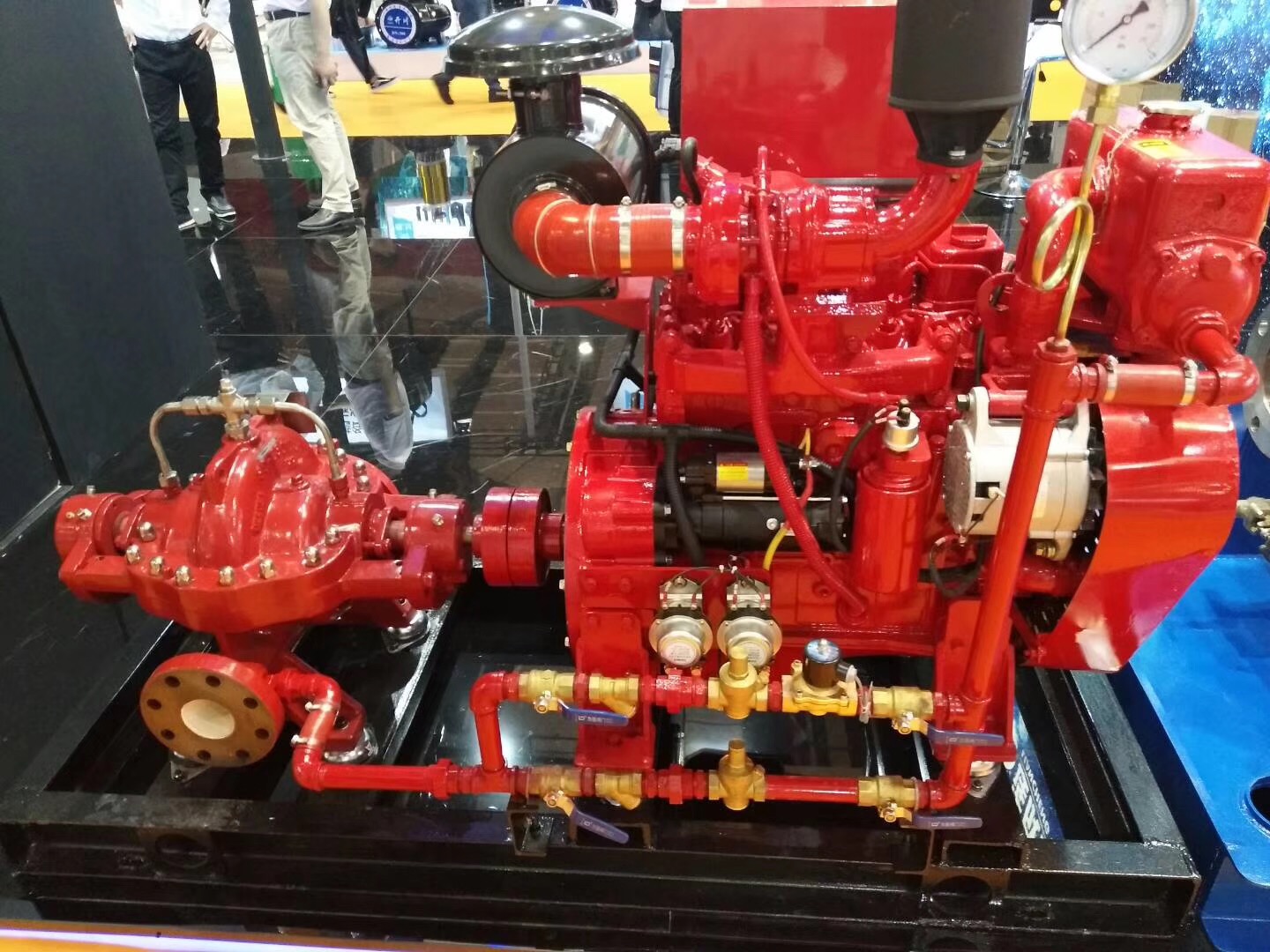

In various industries, the efficient handling of abrasive materials is crucial for productivity and safety. Among the essential tools for this purpose is the slurry pump, a type of pump specifically designed to transport slurries—mixtures of liquid and solid materials. Within this category, OEM (Original Equipment Manufacturer) rubber lined slurry pumps have garnered attention for their durability and efficiency. This article explores the significance of these pumps, their manufacturers, and their advantages across different applications.

Understanding OEM Rubber Lined Slurry Pumps

OEM rubber lined slurry pumps are specially engineered to handle challenging tasks in industries like mining, mineral processing, and wastewater treatment. The rubber lined aspect refers to the protective layer of rubber that coats the pump’s internal components. This lining serves as a barrier against wear and corrosion caused by abrasive particles in the slurry. The design of an OEM pump ensures that it meets rigorous industry standards and provides reliable performance when moving highly concentrated mixtures.

The Role of Manufacturers

The manufacturers of OEM rubber lined slurry pumps play a pivotal role in ensuring that these pumps meet the specific needs of various industries. With the experience and expertise in the field, these OEM manufacturers focus on several key aspects

1. Material Quality High-quality rubber is essential for the longevity of slurry pumps. Leading manufacturers source premium materials that withstand corrosive environments and abrasive conditions.

2. Customization OEM manufacturers often provide customization options to fit specific application needs. Clients can request pumps with varying capacities, sizes, and configurations, allowing for tailored solutions to unique challenges.

3. Technological Advancement Innovative manufacturers keep pace with technological advancements. They often incorporate modern engineering techniques and research findings to improve pump efficiency, reduce energy consumption, and enhance performance.

4. Testing and Quality Assurance Reputable manufacturers subject their products to rigorous testing before market release. This includes performance assessments under different conditions to guarantee reliability and efficiency.

oem rubber lined slurry pump manufacturers

5. After-Sales Support A strong after-sales support system is crucial for users. Reliable manufacturers offer maintenance services, spare parts availability, and operational training to ensure the longevity and efficiency of their pumps.

Advantages of Using Rubber Lined Slurry Pumps

1. Durability The rubber lining significantly extends the lifespan of the pump by protecting it from the abrasive nature of slurries. This results in lower maintenance and replacement costs.

2. Versatility Rubber lined slurry pumps can be used in various applications, including transporting mineral slurries, pulp and paper slurries, and even in wastewater treatment. Their versatility makes them a valuable asset across industries.

3. Efficiency These pumps are designed to handle high flow rates and maintain consistent performance. Their ability to operate efficiently contributes to increased productivity and reduced operational downtime.

4. Reduced Noise Levels Rubber lined pumps tend to produce less noise compared to metal pumps. This aspect can lead to a better working environment, especially in applications where noise levels are a concern.

5. Cost-effectiveness While the initial investment might be significant, the durability, efficiency, and lower maintenance requirements of rubber lined slurry pumps make them a cost-effective solution in the long run.

Conclusion

OEM rubber lined slurry pump manufacturers are essential players in industries that require the effective transport of abrasive slurries. Their commitment to quality, customization, and innovative technologies ensures that these pumps meet the evolving challenges of various sectors. The advantages of using rubber lined slurry pumps, including durability, efficiency, and reduced operational costs, make them a preferred choice for companies seeking reliable solutions in handling challenging materials. As industries continue to evolve, the role of these manufacturers will remain pivotal in providing the necessary tools for efficient and safe operations.

-

Reliable Non-Clog Sewage Pumps with GPT-4-Turbo Tech

NewsAug.04,2025

-

High-Performance Air Pumps for Sand & Gravel | Efficient Transport

NewsAug.03,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Energy Efficiency, Corrosion Resistance

NewsAug.03,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | Energy Efficiency&Compact Design

NewsAug.03,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Low Noise, Durable

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

NewsAug.02,2025