Khmer

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

ធ្នូ . 06, 2024 00:54 Back to list

rubber slurry pump

Understanding Rubber Slurry Pumps An Essential Tool in Various Industries

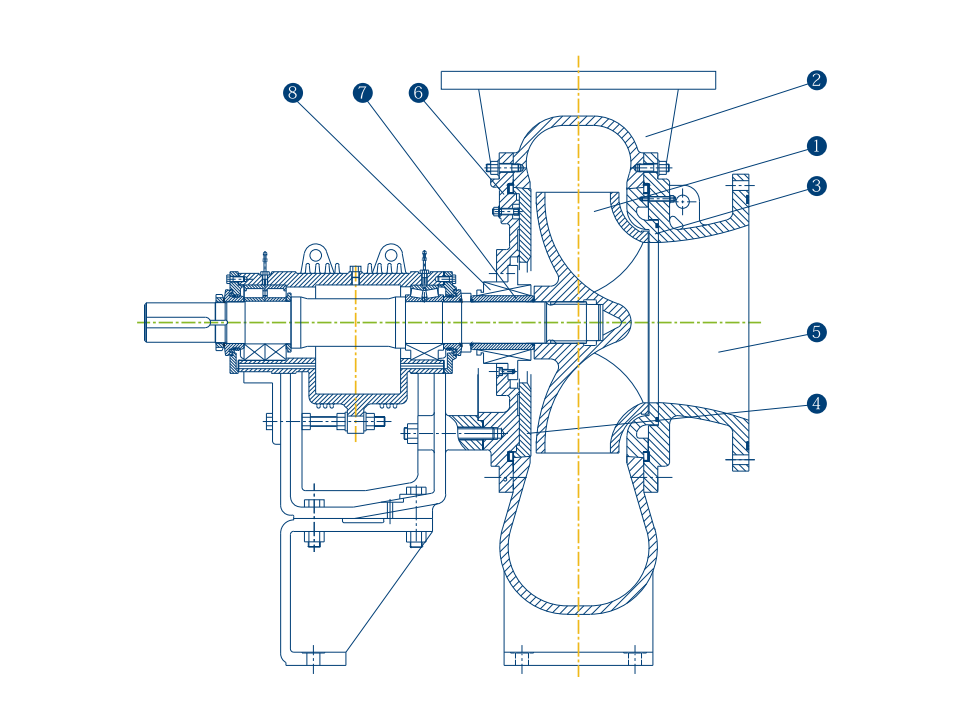

Rubber slurry pumps are specialized mechanical devices designed to handle slurries—mixtures of solids and liquids. These pumps are vital in a multitude of industrial applications, particularly in mining, mineral processing, and construction. Thanks to their durable rubber linings and construction materials, they can withstand the harsh conditions typically associated with slurry handling, such as abrasive materials and corrosive chemicals.

The Principle of Operation

The basic operation of a rubber slurry pump is similar to that of conventional pumps, utilizing centrifugal force to move the slurry. When the pump operates, the impeller spins rapidly, creating a vacuum that draws the slurry into the pump. The slurry is then pushed out through the discharge outlet. This simple yet effective mechanism enables the pump to handle high volumes of viscous materials efficiently.

Rubber slurry pumps are engineered to minimize wear, which is a significant concern when dealing with abrasive materials. The rubber lining provides a flexible and resilient barrier that can absorb the shock of heavy particles, significantly extending the lifespan of the pump compared to metal pumps.

Advantages of Rubber Slurry Pumps

1. Durability The rubber construction makes these pumps exceptionally resistant to abrasion. This characteristic is crucial in industries such as mining, where the slurry can contain gravel, sand, and other abrasive materials that would quickly wear down metal pumps.

2. Corrosion Resistance In addition to being abrasion-resistant, rubber slurry pumps also resist corrosion from various chemicals and materials. This resistance allows for longer operation periods without the need for frequent replacements due to corrosion-related failures.

3. Cost-Effectiveness Although the initial investment in rubber slurry pumps can be higher than traditional pumps, their durability and lower maintenance costs lead to significant savings over time. Businesses save on repairs and replacements, making them a cost-effective option in the long run.

rubber slurry pump

4. Versatility Rubber slurry pumps are adaptable and can be used in various applications, including transporting tailings, sludge, or even heavy-duty chemical processes. This versatility makes them an invaluable asset in many industrial sectors.

Applications in Industries

Rubber slurry pumps are integral in several industries. In the mining sector, they effectively transfer mineral slurries from excavation sites to processing plants. In wastewater treatment, they help manage sludges produced during the treatment processes. Moreover, in construction, these pumps can handle concrete slurry, making them useful for various pouring and mixing processes.

The cement industry also benefits significantly from these pumps, where they are used to transport cement slurries through pipelines. Their ability to handle highly viscous materials with ease ensures that operations run smoothly without significant downtime.

Maintenance and Best Practices

Regular maintenance is key to maximizing the lifespan and performance of rubber slurry pumps. Operators should implement a routine inspection schedule, checking for signs of wear on the rubber linings and seals. Additionally, monitoring the pump's performance metrics, such as flow rate and pressure, can help detect issues before they become serious problems.

Proper installation and operational practices are also crucial. For example, ensuring that the pump is aligned correctly and not subjected to excessive vibration can prevent early wear and tear.

Conclusion

In conclusion, rubber slurry pumps are a critical component in many industrial applications that deal with challenging materials. Their durability, corrosion resistance, and cost-effectiveness make them an excellent choice for any facility looking to optimize its slurry handling processes. By understanding how these pumps operate and implementing best maintenance practices, industries can significantly enhance their operational efficiency and extend the lifespan of their equipment. As industries continue to innovate, the demand for reliable and efficient slurry handling solutions such as rubber slurry pumps will undoubtedly grow, proving their worth in a constantly evolving industrial landscape.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Energy Saving, Low Noise

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump- Chi Yuan Pumps|High Efficiency&Low Noise

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps Co., LTD.|High Efficiency&Energy Conservation

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Advanced Hydraulic Design&Energy-Efficient Solutions

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|energy-efficient fluid handling&industrial durability

NewsJul.30,2025