TEL:

+86 13120555503

Khmer

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

កុម្ភៈ . 12, 2025 12:42 Back to list

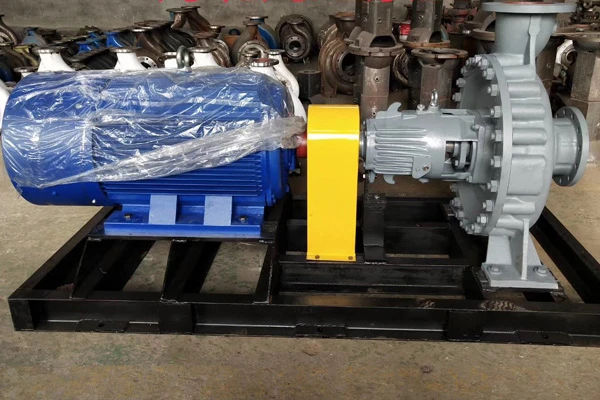

Horizontal Split Case Pump

Double suction pumps have long been hailed as a crucial component in various industries, offering a myriad of advantages that optimize performance and efficiency. Their design inherently provides a balanced and stable hydraulic environment, making them indispensable in sectors that demand high fluid volume transportation with precision and reliability.

Moreover, the design of double suction pumps contributes significantly to their low maintenance requirements. The symmetric design not only balances hydraulic forces but also simplifies maintenance procedures. With fewer components exposed to uneven wear, routine checks and part replacements are reduced, thereby lowering maintenance costs and downtime. This reliability is critical for industries where uptime is paramount, guaranteeing consistent operational flow and productivity. In terms of expertise, double suction pumps are engineered with precision and are the result of advanced fluid dynamics and material sciences. Manufacturers invest in extensive research and development to refine pump technologies, contributing to the pumps' durability and performance enhancements. Implementing double suction pumps means entrusting a product designed with deep industry knowledge, ensuring high standards of safety and functionality. From an authoritative standpoint, double suction pumps are backed by numerous certifications and industry standards, showcasing their reliability and performance across varying applications. Institutions that utilize these pumps benefit from not only the immediate operational advantages but also long-term value through compliance with stringent industry regulations and standards, such as those set by the API (American Petroleum Institute) for industrial equipment. Finally, in terms of trustworthiness, case studies and testimonials from global enterprises deploying double suction pumps provide compelling evidence of their effectiveness and efficiency. Real-world applications illustrate their benefits, highlighting successful implementations that underscore both economic and performance advantages, thereby assuring stakeholders of their investment's value. In conclusion, double suction pumps are a cornerstone of efficient fluid management across multiple industries. Their design ingenuity leads to reduced maintenance, lower energy consumption, and the ability to handle substantial fluid volumes with unparalleled reliability. By integrating double suction pumps, industries not only optimize their operations but also achieve significant cost savings, operational efficiency, and meet regulatory compliance, making them an obvious choice for modern fluid handling requirements.

Moreover, the design of double suction pumps contributes significantly to their low maintenance requirements. The symmetric design not only balances hydraulic forces but also simplifies maintenance procedures. With fewer components exposed to uneven wear, routine checks and part replacements are reduced, thereby lowering maintenance costs and downtime. This reliability is critical for industries where uptime is paramount, guaranteeing consistent operational flow and productivity. In terms of expertise, double suction pumps are engineered with precision and are the result of advanced fluid dynamics and material sciences. Manufacturers invest in extensive research and development to refine pump technologies, contributing to the pumps' durability and performance enhancements. Implementing double suction pumps means entrusting a product designed with deep industry knowledge, ensuring high standards of safety and functionality. From an authoritative standpoint, double suction pumps are backed by numerous certifications and industry standards, showcasing their reliability and performance across varying applications. Institutions that utilize these pumps benefit from not only the immediate operational advantages but also long-term value through compliance with stringent industry regulations and standards, such as those set by the API (American Petroleum Institute) for industrial equipment. Finally, in terms of trustworthiness, case studies and testimonials from global enterprises deploying double suction pumps provide compelling evidence of their effectiveness and efficiency. Real-world applications illustrate their benefits, highlighting successful implementations that underscore both economic and performance advantages, thereby assuring stakeholders of their investment's value. In conclusion, double suction pumps are a cornerstone of efficient fluid management across multiple industries. Their design ingenuity leads to reduced maintenance, lower energy consumption, and the ability to handle substantial fluid volumes with unparalleled reliability. By integrating double suction pumps, industries not only optimize their operations but also achieve significant cost savings, operational efficiency, and meet regulatory compliance, making them an obvious choice for modern fluid handling requirements.

Share

Latest news

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency & Energy Conservation

NewsAug.08,2025

-

ISG Series Vertical Pipeline Pump|Energy Efficiency&Durability

NewsAug.08,2025

-

Heavy-Duty Submersible Sludge Pump | High Performance Solutions

NewsAug.08,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Energy Efficiency & Low Noise

NewsAug.08,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

NewsAug.07,2025

-

ISG Series Pipeline Pump-Chi Yuan Pumps|High Efficiency, Low Noise

NewsAug.07,2025