TEL:

+86 13120555503

Georgian

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

თებ . 11, 2025 18:58 Back to list

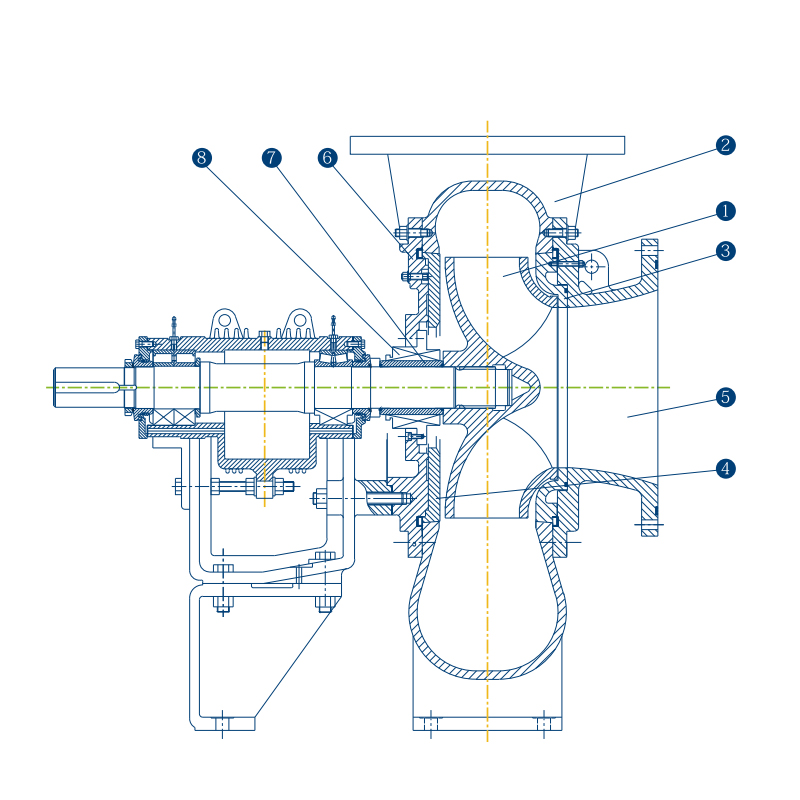

double suction centrifugal pump diagram

A double suction centrifugal pump is a critical component in numerous industrial applications, revered for its efficiency and effectiveness in handling large volumes of fluid. At its core, this pump is a marvel of engineering designed to enhance operational reliability and efficiency, making it indispensable in settings like water treatment plants, chemical processing, and large-scale manufacturing facilities. Its design differentiates it significantly from other pump types, offering unique benefits that cater to specific industrial needs.

Moreover, double suction centrifugal pumps are lauded for their energy efficiency. With their design allowing smoother, less turbulent fluid flow, they typically consume less power than their single suction counterparts. This not only reduces operational costs but also aligns with broader sustainability goals by minimizing energy consumption. Implementing a double suction centrifugal pump in an industrial setup involves considering factors such as the specific gravity of the fluid, temperature and pressure requirements, and the desired flow speed. Selecting the right pump requires expertise, often necessitating consultation with manufacturers or engineers to ensure compatibility with existing systems and adherence to operational standards. This level of professional engagement ensures that the selected pump design can accommodate the nuances of the intended application, providing reliable service for years to come. In conclusion, the double suction centrifugal pump is an exemplary piece of technology that combines efficiency, durability, and adaptability. Its ability to handle high volume and pressure applications with ease makes it a favorite in industries seeking reliable fluid transfer solutions. By balancing complex hydraulic forces, it not only improves operational efficiency but also extends the lifecycle of pumping systems, thereby providing a sustainable advantage in industrial practices. Investing in such technology is not just about meeting current operational demands but also future-proofing industrial processes against evolving technical and environmental challenges.

Moreover, double suction centrifugal pumps are lauded for their energy efficiency. With their design allowing smoother, less turbulent fluid flow, they typically consume less power than their single suction counterparts. This not only reduces operational costs but also aligns with broader sustainability goals by minimizing energy consumption. Implementing a double suction centrifugal pump in an industrial setup involves considering factors such as the specific gravity of the fluid, temperature and pressure requirements, and the desired flow speed. Selecting the right pump requires expertise, often necessitating consultation with manufacturers or engineers to ensure compatibility with existing systems and adherence to operational standards. This level of professional engagement ensures that the selected pump design can accommodate the nuances of the intended application, providing reliable service for years to come. In conclusion, the double suction centrifugal pump is an exemplary piece of technology that combines efficiency, durability, and adaptability. Its ability to handle high volume and pressure applications with ease makes it a favorite in industries seeking reliable fluid transfer solutions. By balancing complex hydraulic forces, it not only improves operational efficiency but also extends the lifecycle of pumping systems, thereby providing a sustainable advantage in industrial practices. Investing in such technology is not just about meeting current operational demands but also future-proofing industrial processes against evolving technical and environmental challenges.

Share

Next:

Latest news

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency & Energy Conservation

NewsAug.08,2025

-

ISG Series Vertical Pipeline Pump|Energy Efficiency&Durability

NewsAug.08,2025

-

Heavy-Duty Submersible Sludge Pump | High Performance Solutions

NewsAug.08,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Energy Efficiency & Low Noise

NewsAug.08,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

NewsAug.07,2025

-

ISG Series Pipeline Pump-Chi Yuan Pumps|High Efficiency, Low Noise

NewsAug.07,2025