TEL:

+86 13120555503

Italian

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Feb . 13, 2025 18:41 Back to list

Pipeline Pump

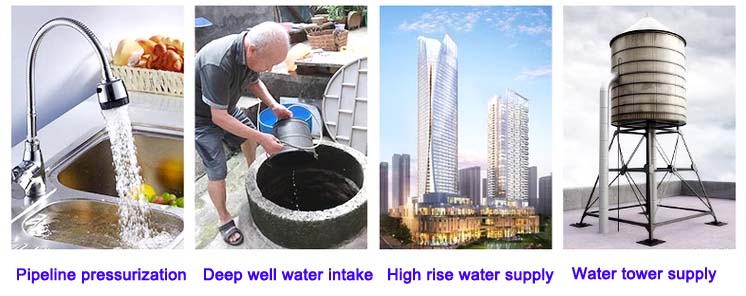

Pipeline pumping systems are integral components in various industrial processes, powering the efficient movement of liquids and gases through pipelines with precision and reliability. As the backbone of numerous sectors, including oil and gas, water treatment, and chemical processing, these systems require an in-depth understanding of engineering principles, advanced technology, and maintenance strategies to maximize their efficacy and lifespan.

Trustworthiness of pipeline pumping systems hinges upon adherence to industry standards and safety regulations. Compliance with bodies such as the American Petroleum Institute (API) and the International Organization for Standardization (ISO) ensures that the systems meet rigorous safety and performance criteria. Moreover, operators must maintain meticulous records of inspections and repairs, which is crucial for continuous improvement and accountability in system management. In reinforcing the reliability of a pipeline pumping system, it is also vital to foster comprehensive training programs, empowering stakeholders with the necessary skills to manage and troubleshoot these intricate systems effectively. Educational initiatives should include hands-on training and theoretical instruction, fostering a workforce capable of upholding the highest standards of operational excellence. Authoritativeness in the field of pipeline pumping is exemplified by partnerships with industry leaders, participation in technical forums, and contributions to academic publications. Engaging with a community of experts stimulates innovation and underscores a commitment to advancing the technology and practices in pipeline pumping. In summary, the multifaceted domain of pipeline pumping calls for a confluence of experience, expertise, authoritativeness, and trustworthiness. By integrating best practices in system design, materials choice, technological advancements, and maintenance strategies, industry professionals can ensure these systems operate with optimal efficiency and reliability. This not only boosts productivity but also reinforces safety, setting the standard for excellence in pipeline pumping operations across the globe. Through dedication to continuous learning and development, the future of pipeline pumping systems looks promising, driven by innovation and an unwavering commitment to quality.

Trustworthiness of pipeline pumping systems hinges upon adherence to industry standards and safety regulations. Compliance with bodies such as the American Petroleum Institute (API) and the International Organization for Standardization (ISO) ensures that the systems meet rigorous safety and performance criteria. Moreover, operators must maintain meticulous records of inspections and repairs, which is crucial for continuous improvement and accountability in system management. In reinforcing the reliability of a pipeline pumping system, it is also vital to foster comprehensive training programs, empowering stakeholders with the necessary skills to manage and troubleshoot these intricate systems effectively. Educational initiatives should include hands-on training and theoretical instruction, fostering a workforce capable of upholding the highest standards of operational excellence. Authoritativeness in the field of pipeline pumping is exemplified by partnerships with industry leaders, participation in technical forums, and contributions to academic publications. Engaging with a community of experts stimulates innovation and underscores a commitment to advancing the technology and practices in pipeline pumping. In summary, the multifaceted domain of pipeline pumping calls for a confluence of experience, expertise, authoritativeness, and trustworthiness. By integrating best practices in system design, materials choice, technological advancements, and maintenance strategies, industry professionals can ensure these systems operate with optimal efficiency and reliability. This not only boosts productivity but also reinforces safety, setting the standard for excellence in pipeline pumping operations across the globe. Through dedication to continuous learning and development, the future of pipeline pumping systems looks promising, driven by innovation and an unwavering commitment to quality.

Share

Next:

Latest news

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency & Energy Conservation

NewsAug.08,2025

-

ISG Series Vertical Pipeline Pump|Energy Efficiency&Durability

NewsAug.08,2025

-

Heavy-Duty Submersible Sludge Pump | High Performance Solutions

NewsAug.08,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Energy Efficiency & Low Noise

NewsAug.08,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

NewsAug.07,2025

-

ISG Series Pipeline Pump-Chi Yuan Pumps|High Efficiency, Low Noise

NewsAug.07,2025