Armenian

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Նյմ . 12, 2024 23:42 Back to list

end suction pump

Understanding End Suction Pumps A Comprehensive Overview

End suction pumps are one of the most commonly used types of centrifugal pumps in various industries today. Known for their simple design and reliable operation, these pumps can handle a wide range of fluids and are employed in applications from municipal water supply systems to industrial processes.

Design and Operation

The fundamental design of an end suction pump features a volute casing that houses the impeller, which is mounted on a shaft. The name end suction comes from the fact that the fluid enters the pump through a suction inlet located at the end of the pump, making it easy to configure within a pipeline system.

When the pump operates, the rotating impeller draws fluid into the eye of the impeller. The centrifugal force generated by the impeller effectively converts mechanical energy into kinetic energy, pushing the fluid out through the pump’s discharge port. This straightforward but effective mechanism has made end suction pumps a preferred choice for many applications.

Key Features

1. Versatility End suction pumps can handle a variety of fluids, including water, wastewater, chemicals, and slurries. This versatility allows for broader usage across different sectors.

2. Efficiency When properly designed and maintained, these pumps can achieve high levels of efficiency. Their simple construction tends to lead to lower energy consumption compared to more complex pumping systems.

3. Maintenance End suction pumps are generally easy to maintain. Many designs allow for the impeller and other internal components to be accessed without removing the pump from the piping system. This reduces downtime and maintenance costs significantly.

4. Compact Design The end suction configuration typically requires less space than other pump designs, such as vertical turbine pumps, making them suitable for areas with limited installation space.

end suction pump

Applications

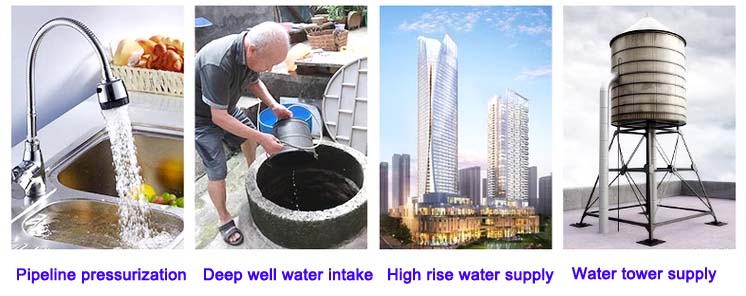

End suction pumps are widely used in a variety of applications

- Water Supply They play a pivotal role in water treatment plants, municipal water distribution systems, and agricultural irrigation systems. - Industrial Applications In industrial settings, these pumps are used for transferring chemicals, oils, and other substances that require reliable pumping solutions. - Building Services HVAC systems often incorporate end suction pumps for circulating water in heating and cooling applications. - Fire Protection Systems Their reliability makes them vital for fire suppression systems in buildings and industrial facilities.

Advantages and Disadvantages

While end suction pumps have numerous advantages, there are also some disadvantages to consider

Advantages - Reliable operation with reduced risk of failure. - Cost-effective compared to more complex pumping systems. - Easy installation and integration within existing infrastructure.

Disadvantages - Limited capability for handling large solids or highly viscous fluids, which may require alternative pump types. - Performance can be affected by variations in fluid viscosity and temperature.

Conclusion

In summary, end suction pumps are an integral component of many fluid transfer systems across various industries. Their straightforward design, coupled with their versatility and efficiency, positions them as a favorable choice for users seeking a reliable pumping solution. Understanding the operational principles, advantages, and limitations of end suction pumps enables engineers and managers to make informed decisions that optimize performance and efficiency in their applications. As technology advances, these pumps continue to evolve, incorporating new materials and designs to meet the ever-changing demands of diverse industries.

-

Custom Drilling Mud and Slurry Pump Supplier - High Efficiency, Tailored Solutions

NewsJun.10,2025

-

Supply Vertical Submersible Sewage Pump High-Efficiency WQ/QW Pumps Supplier

NewsJun.10,2025

-

Premium Sewage Ejection System & Pumps Efficient Waste Removal

NewsJun.09,2025

-

Premium Wholesale Slurry Pump Impellers Durable & Efficient Slurry Handling

NewsJun.09,2025

-

Top Sewage Pump Companies Durable Industrial Solutions for Efficiency

NewsJun.09,2025

-

Heavy Duty Slurry Pumps - OEM High Performance & Bulk Wholesale

NewsJun.09,2025