Hungarian

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

júl . 28, 2024 23:21 Back to list

Understanding the Working Principles and Applications of Centrifugal Double Suction Pumps in Industry

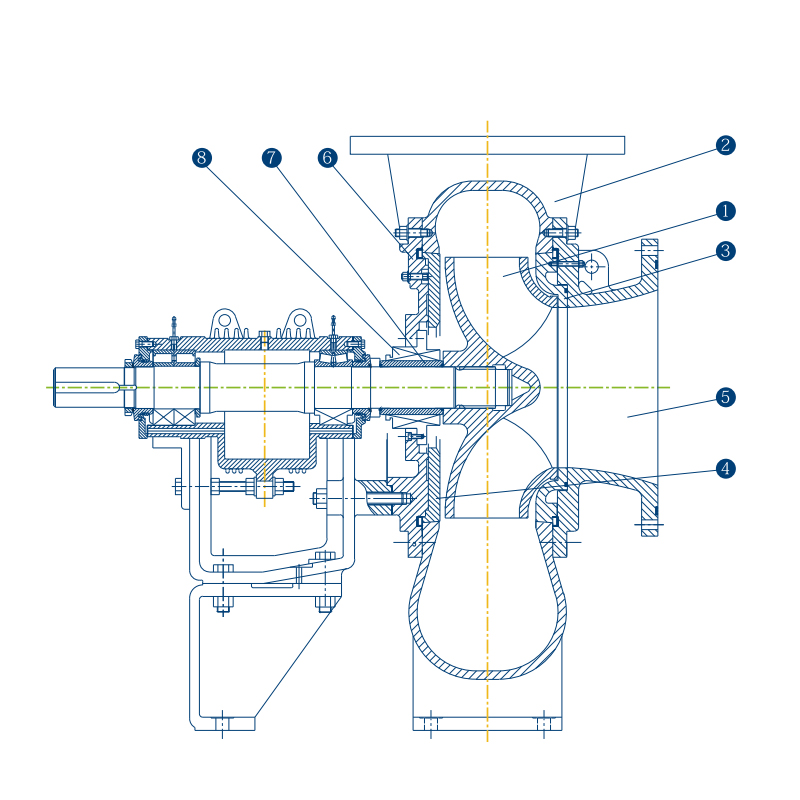

Understanding Centrifugal Double Suction Pumps A Comprehensive Overview

Centrifugal double suction pumps are significant components widely utilized in various industrial applications, particularly in water and wastewater treatment, power generation, and chemical processing. These pumps are specifically designed to handle large flow rates with high efficiency, making them ideal for tasks that require the transport of fluids across considerable distances.

Design and Functionality

The centrifugal double suction pump features a unique design that sets it apart from single suction pumps. As the name implies, double suction pumps have two impellers that draw fluid from both sides of the pump casing. This configuration balances the hydraulic forces acting on the impeller, significantly reducing axial thrust. This design not only prolongs the lifespan of the pump but also improves its operational efficiency.

When the pump operates, the impellers rotate and impart kinetic energy to the fluid, converting it into pressure energy as the fluid moves from the impeller into the volute or diffuser. This increase in pressure allows the fluid to be transported effectively through pipelines. The dual suction design facilitates a higher flow rate with lower energy consumption compared to single suction pumps, making it a preferred choice in applications requiring substantial fluid movement.

Applications

Centrifugal double suction pumps are versatile and find application in several sectors. One of the largest applications is in water supply systems, where they are employed to pump water from reservoirs to treatment plants, irrigation systems, and municipal supply networks. Additionally, in power generation, these pumps are crucial for circulating cooling water, ensuring that the operational temperatures remain within safe limits.

centrifugal double suction pump

In the oil and gas industry, these pumps are utilized to move crude oil and refined products, handling the often abrasive and viscous nature of the fluids involved. Furthermore, in the chemical industry, they transport corrosive materials, necessitating the use of specialized materials for pump construction to prevent wear and damage.

Advantages

The centrifugal double suction pump brings numerous advantages to various operations. The primary benefit is its ability to handle high flow rates while maintaining efficiency. The design reduces vibrations and noise, promoting a quieter working environment. Moreover, the balanced operation leads to lower energy consumption, resulting in cost savings over time.

The robustness of double suction pumps makes them suitable for high-capacity systems, and because they can handle a range of fluids with different viscosities, they offer flexibility in their applications. Their maintenance is typically easier than that of other pump types, given the availability of standard components and their straightforward design.

Conclusion

Centrifugal double suction pumps represent a sophisticated solution for fluid transport needs across multiple industries. Their unique design addresses the challenges of high flow rates and energy efficiency, which are crucial in today’s industrial landscape. As industries continue to evolve, the demand for efficient, reliable, and robust pumping solutions like the centrifugal double suction pump is likely to grow, reinforcing their importance in the engineering and manufacturing sectors. With advancements in materials and technology, these pumps will undoubtedly continue to be a vital part of fluid management systems worldwide.

-

Heavy-Duty Mining Sludge Pumps - Wear-Resistant Slurry Handling

NewsAug.02,2025

-

Horizontal Split Case Pump with GPT-4 Turbo | High Efficiency

NewsAug.01,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

NewsAug.01,2025

-

Advanced Flue Gas Desulfurization Pump with GPT-4 Turbo | Durable & Efficient

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Hydraulic Design&Durable Construction

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Energy Efficient & Low Noise

NewsJul.31,2025