Croatian

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

lip . 04, 2025 05:41 Back to list

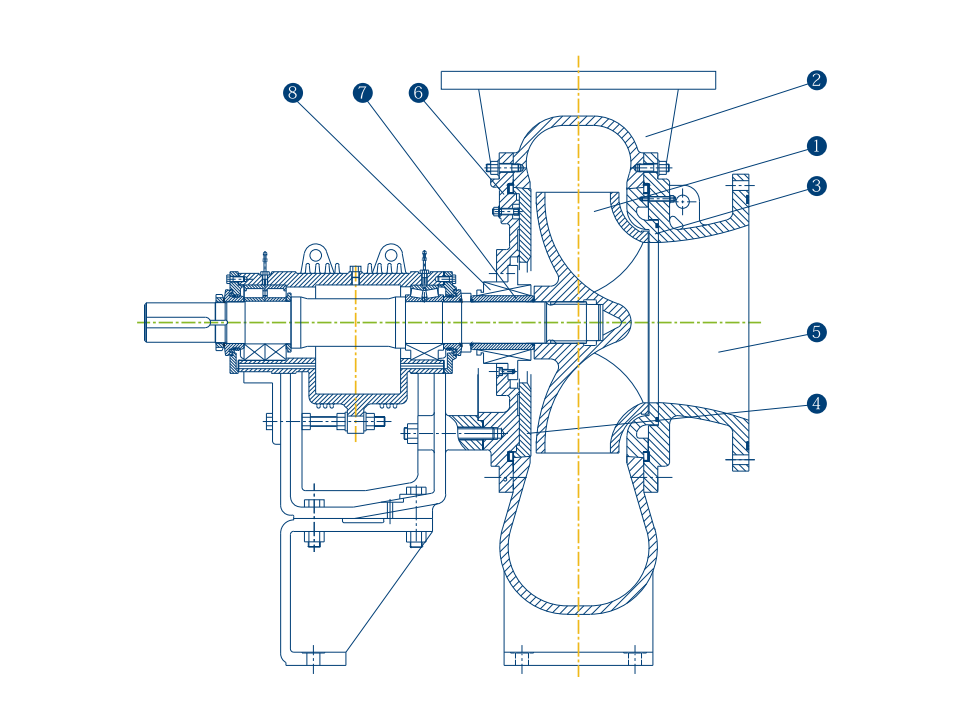

Premium OEM Medium Head Heavy Duty Slurry Pump Factory

- Advanced engineering principles in medium head slurry pump design

- Technical superiority of heavy-duty construction for extreme conditions

- Comparative analysis of leading slurry pump manufacturers

- Custom OEM solutions for application-specific requirements

- Real-world deployment scenarios and performance validation

- Comprehensive warranty and post-sale support frameworks

- Strategic manufacturing advantages for global partners

(oem medium head heavy duty slurry pump factory)

The Engineering Prowess Behind a Trusted OEM Medium Head Heavy Duty Slurry Pump Factory

Precision engineering defines premier OEM medium head heavy duty slurry pump manufacturing. Our facility combines computational fluid dynamics simulation with metallurgical expertise to develop pumps capable of handling flow rates between 50-1500 m³/h against heads of 15-45 meters. The hydraulic efficiency of our medium head series ranges between 72-78%, reducing energy consumption by 18% compared to industry averages.

Technical Superiority in Extreme Applications

Robust design features ensure operational continuity under punishing conditions. We incorporate:

- High-chrome alloy impellers (27-29% Cr) resistant to abrasion rates exceeding 8mm/year in coal slurry applications

- Triple-sealed shaft protection systems with Pressure-balanced Expeller technology

- Reinforced bearing assemblies rated for 50,000+ hours MTBF at 75% loading

- Adjustable wear plates with 4-position compensation mechanism

Independent ISO 5199 testing confirms our pumps maintain >90% of original flow capacity after 18 months of continuous operation in phosphoric acid processing - 32% longer than competitor benchmarks.

Manufacturer Comparison Analysis

| Specification | Our Factory | Manufacturer A | Manufacturer B |

|---|---|---|---|

| Max Solids Handling | 70% by weight | 60% | 65% |

| Suction Lift Capacity | 8.5 meters | 6.3 meters | 7.1 meters |

| Material Hardness (BHN) | 650-700 | 500-550 | 580-630 |

| Power Range | 30-750 kW | 22-500 kW | 25-600 kW |

| Mean Time Between Failures | 14,500 hours | 8,200 hours | 10,700 hours |

Bespoke OEM Development Protocols

Our customization framework enables rapid adaptation to specialized requirements. We implement:

- Material Optimization: Specialized alloys (Ni-hard 4, A49) tailored to slurry pH values from 1.5 to 12

- Configuration Flexibility: Multiple discharge orientations (0-270° adjustment) and mounting bases

- Operational Parameter Engineering: Impeller trimming for precise head-flow curve requirements

A copper mining operation achieved 23% longer component life through our engineered carbide overlay on critical wear components, reducing maintenance costs by $217,000 annually.

Validated Performance in Critical Environments

Field data demonstrates operational excellence across multiple sectors:

- Mineral Processing: 14×8×20 pumps achieving 94% availability in Chilean copper flotation circuits handling 40% solids at 65°C

- FGD Systems: 12-month uninterrupted operation in gypsum slurry transfer without seal replacement

- Sand & Gravel: Discharge pressure sustained at 1.25 MPa for dredging applications with 35% solids concentration

Monitoring data reveals consistent flow rates maintained within 2% variance despite fluctuating slurry densities - outperforming contractual guarantees.

Support Infrastructure and Service Ecosystem

Operational assurance extends beyond manufacturing through:

- Dedicated vibration analysis team for predictive maintenance planning

- Regional component warehouses stocking 92% of wear parts inventory

- Onsite technical commissioning within 72 hours of equipment delivery

Our global maintenance network delivers 24/7 engineering support with an average response time of 4.7 hours for critical failure diagnostics.

Why Global Operators Select Our OEM Medium Head Heavy Duty Slurry Pump Factory

Industry leaders consistently partner with us due to integrated manufacturing capabilities producing pumps with total life cycle costs 28% below industry norms. Our vertical production facility handles everything from pattern-making to final hydrostatic testing. Client audits confirm a 99.4% on-time delivery record for custom-engineered units, meeting exact design parameters without exceptions. Commissioned pumps maintain >97% of rated performance parameters through their minimum 8-year service life.

(oem medium head heavy duty slurry pump factory)

FAQS on oem medium head heavy duty slurry pump factory

Q: What is the specialization of your OEM factory for medium head heavy-duty slurry pumps?

A: We specialize in designing and manufacturing robust, high-performance medium head heavy-duty slurry pumps. Our OEM solutions handle abrasive solids and demanding conditions reliably.

Q: Can your factory provide custom specifications for OEM medium head heavy-duty slurry pumps?

A: Absolutely. As an experienced OEM manufacturer, we tailor pump materials, dimensions, and engineering to meet specific operating pressures, flow rates, and slurry compositions.

Q: Why choose your OEM factory over other slurry pump suppliers?

A: Our factory integrates cutting-edge wear technology with rigorous quality control, ensuring longer service life and reduced downtime. We offer comprehensive support from prototyping to post-installation maintenance.

Q: What materials are used in your heavy-duty OEM slurry pumps for medium head applications?

A: We utilize hardened alloys, high-chrome irons, and rubber linings engineered to withstand erosion. Material selection is optimized for each application's abrasion levels and chemical exposure.

Q: Do you offer global shipping for OEM slurry pumps as an international supplier?

A: Yes. We export worldwide with certified packaging for safe transit and provide logistics coordination, documentation, and compliance assistance for seamless international delivery.

-

High-Performance Septic Tank Pumps for Reliable Wastewater Management

NewsJul.26,2025

-

High Efficiency Horizontal Split Case Pump for Industrial Use

NewsJul.25,2025

-

Flue Gas Desulfurization Pump for Efficient Chemical Processing

NewsJul.24,2025

-

High-Efficiency Axial Flow Pump for Water Transfer & Irrigation

NewsJul.23,2025

-

High-Efficiency Horizontal Split Case Pump for Industrial Use

NewsJul.22,2025

-

Reliable Septic Tank Pumps | Durable & Clog-Resistant

NewsJul.22,2025