Hindi

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

नवम्बर . 18, 2024 15:26 Back to list

High-quality OEM rubber-lined slurry pump for exceptional performance and durability

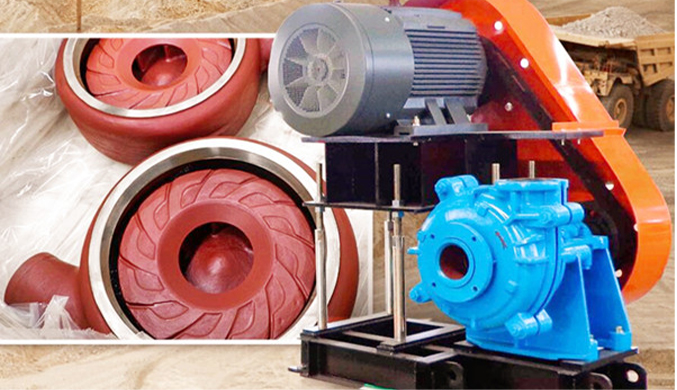

Top-Notch OEM Rubber Lined Slurry Pump for Superior Performance

In the world of industrial applications, the need for reliable and efficient equipment is paramount. Among such essential tools, slurry pumps play a critical role in the transfer of abrasive fluids and high-solid-content mixtures. Particularly, top-notch Original Equipment Manufacturer (OEM) rubber lined slurry pumps have emerged as one of the best solutions in handling challenging pumping tasks in various industries.

What is a Rubber Lined Slurry Pump?

A rubber lined slurry pump is designed to transport slurries, which are mixtures of liquid and solid particles. These pumps are specifically engineered to handle the erosive and corrosive nature of slurries, making them invaluable in sectors such as mining, mineral processing, construction, and wastewater management. The rubber lining offers enhanced protection against wear and tear caused by the abrasive materials present in slurry mixtures.

Advantages of Using Rubber Lined Slurry Pumps

1. Wear Resistance

One of the most significant advantages of rubber lined slurry pumps is their exceptional wear resistance. The rubber lining absorbs impact and reduces abrasion, significantly extending the lifespan of the pump. This durability is particularly advantageous in environments where the pump operates continuously under adverse conditions.

Beyond just wear, rubber lining also provides excellent resistance to corrosion. In industries that deal with chemically aggressive slurries, the rubber material acts as a barrier, preventing damaging interactions between the slurry and the pump components. This ensures not only the integrity of the pump but also minimizes the risk of operational downtime caused by equipment failure.

'top-notch oem rubber lined slurry pump for superior ...'

3. Cost Efficiency

Investing in a high-quality OEM rubber lined slurry pump proves to be a cost-effective decision in the long run. Although the initial purchase price may be higher compared to other pumps, the pump's durability and reduced maintenance needs lead to lower operational costs. Additionally, fewer replacements and repairs contribute to significant savings over time.

4. Versatility

Rubber lined slurry pumps are highly versatile and can handle various types of slurries, including those found in the mining, sugar, and chemical industries. They are capable of pumping a wide range of solid sizes and concentrations, making them suitable for diverse applications. This adaptability makes them an asset in any industrial setting.

Choosing the Right OEM Provider

When selecting a rubber lined slurry pump, choosing a reputable OEM provider is essential. A top-notch OEM will not only supply high-quality products but will also offer support in terms of installation, maintenance, and spare parts. Customization options may also be available, allowing businesses to tailor the pumps to their specific operational needs.

Conclusion

In conclusion, top-notch OEM rubber lined slurry pumps are indispensable tools in the industrial sector, providing superior performance, durability, and efficiency in managing abrasive and corrosive slurries. Their advantages in wear and corrosion resistance, cost savings, and versatility, coupled with the selection of a credible OEM provider, ensure that industries can operate smoothly and effectively, even under the most demanding conditions. By investing in high-quality slurry pumps, companies can enhance their productivity and maintain a competitive edge in their respective markets.

-

China Small Slurry Pump Manufacturer - High Efficiency Small Centrifugal Slurry Pumps for Mining & Industry

NewsJun.24,2025

-

Custom Drilling Mud and Slurry Pump Supplier - High Efficiency, Tailored Solutions

NewsJun.10,2025

-

Supply Vertical Submersible Sewage Pump High-Efficiency WQ/QW Pumps Supplier

NewsJun.10,2025

-

Premium Sewage Ejection System & Pumps Efficient Waste Removal

NewsJun.09,2025

-

Premium Wholesale Slurry Pump Impellers Durable & Efficient Slurry Handling

NewsJun.09,2025

-

Top Sewage Pump Companies Durable Industrial Solutions for Efficiency

NewsJun.09,2025