Hebrew

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

ספט . 16, 2024 09:33 Back to list

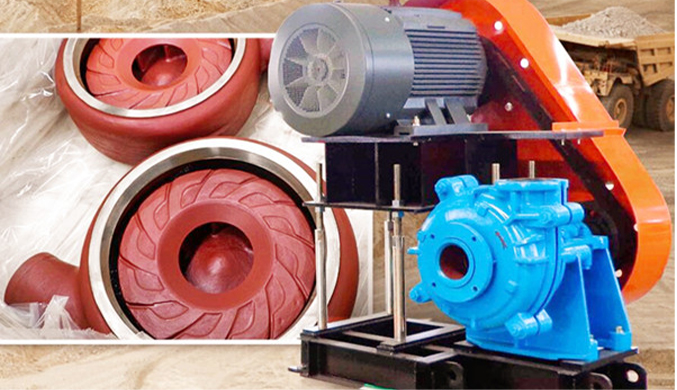

High-Performance Diesel Slurry Pumps for Efficient Material Handling

The Diesel Slurry Pump An Indispensable Tool for Heavy-Duty Applications

In various industries, particularly in mining, construction, and dredging, the transportation of slurry—a mixture of solid particles and liquid—is a common requirement. To efficiently and effectively manage this task, the diesel slurry pump stands out as an essential piece of equipment. This article delves into the functionality, benefits, and applications of diesel slurry pumps.

Understanding Diesel Slurry Pumps

A diesel slurry pump is a type of centrifugal pump specifically designed to handle the transportation of abrasive and corrosive materials. Unlike standard pumps, diesel slurry pumps are built with robust materials to withstand the rigors of moving heavy slurries that contain solids such as sand, gravel, or sludge. Typically powered by a diesel engine, these pumps can operate in environments where electric power supply is limited or non-existent, providing a reliable solution for remote operations.

Key Features and Components

Diesel slurry pumps are characterized by several key components that enhance their efficiency and durability. These include

1. High-Chrome Alloys Many slurry pumps are constructed from wear-resistant materials, often high-chrome alloys, which provide extended life even under abrasive conditions. 2. Heavy-Duty Bearings These pumps are equipped with robust bearings that can handle the heavy loads and ensure smooth operation over extended periods.

4. Self-Priming Mechanisms Many models include self-priming features, making it easier to start and operate in varying conditions without the need for additional equipment.

Benefits of Using Diesel Slurry Pumps

diesel slurry pump

The use of diesel slurry pumps offers several advantages

1. Mobility As they are typically mounted on trailers or skids, diesel slurry pumps are highly portable. This mobility allows for easy setup and relocation on job sites, making them ideal for projects that require frequent moves.

2. Efficiency Diesel engines are known for their power and efficiency, making these pumps capable of handling large volumes of slurry quickly and effectively. This capability can significantly reduce the time and labor costs associated with transporting materials.

3. Powerful Performance Diesel slurry pumps can deliver high pressures and flows, essential for moving heavy slurries over long distances or through challenging terrains.

4. Operational Flexibility Unbound by electrical power requirements, these pumps can be operated in remote locations, ensuring that projects can proceed regardless of the availability of local utilities.

Applications

Diesel slurry pumps are employed in a variety of applications, including

- Mining Operations For transporting mined materials mixed with water. - Construction Sites To manage site runoff or dewater excavations. - Dredging Projects In maintaining waterways by removing sediment and debris. - Wastewater Treatment For pumping sludge in treatment facilities.

Conclusion

In summary, diesel slurry pumps are vital for efficient slurry transport across multiple industries. Their robust design, combined with the power and efficiency of diesel engines, ensures that they can handle the toughest jobs in the most challenging environments. As industries continue to evolve and demand efficient solutions, the importance of diesel slurry pumps will undoubtedly grow, reinforcing their role as indispensable tools in heavy-duty applications.

-

Air Pump Sand & Gravel: Efficient Cleaning & Transfer

NewsAug.11,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High-Efficiency Centrifugal Pump, Corrosion-Resistant Design

NewsAug.11,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

NewsAug.11,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps|Industrial Fluid Handling&Water Supply

NewsAug.11,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps|Industrial Fluid Handling,High Efficiency

NewsAug.11,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency&Energy Conservation

NewsAug.11,2025