hausa

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Nov . 24, 2024 10:11 Back to list

axial pump

Understanding Axial Pumps Design and Applications

Axial pumps are a type of positive-displacement pump that are widely used in various industries for their efficient handling of fluids. Unlike centrifugal pumps, where the flow direction is radial, axial pumps operate by moving fluid along the axis of the pump, hence the name. This design allows them to maintain a consistent flow while providing high efficiency, especially in applications requiring large volumes of fluid movement with relatively low pressure.

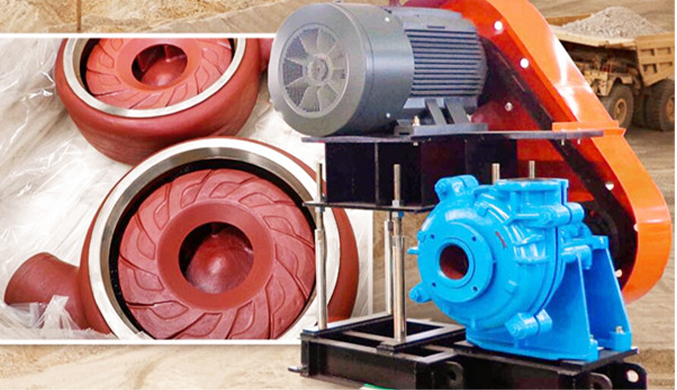

One of the primary components of an axial pump is the impeller, which is designed with blades that push the fluid in a straight path. As the impeller rotates, it draws fluid into the pump and accelerates it along the discharge line. This mechanism facilitates a rapid and steady flow, which makes axial pumps particularly suitable for applications such as cooling systems, irrigation, and even in the maritime industry for moving water efficiently.

axial pump

Axial pumps are particularly favored in situations where high flow rates are necessary. For instance, they are widely used in power generation plants, where cooling water needs to be circulated through turbines. The ability to handle large volumes with minimal pressure loss makes them an essential component in these settings. Additionally, in agricultural applications, axial pumps assist in irrigation systems, helping to deliver water over long distances, ensuring that crops receive adequate nourishment.

These pumps are also celebrated for their relatively simple design, which leads to lower maintenance costs compared to more complex pump systems. However, they do have limitations. For example, axial pumps are less effective at generating high pressure, which can restrict their use in certain applications where pressure is critical. Therefore, it is essential to carefully consider the specific requirements of a project before opting for axial pump technology.

In conclusion, axial pumps play a vital role in various sectors due to their efficiency and straightforward operational design. They are particularly beneficial in applications that require high flow rates and relatively low pressure. As technology advances, the design and materials used in axial pumps continue to improve, expanding their applications and enhancing their performance. For industries reliant on fluid movement, understanding axial pumps and their advantages can lead to more effective and efficient operational strategies.

-

Custom Drilling Mud and Slurry Pump Supplier - High Efficiency, Tailored Solutions

NewsJun.10,2025

-

Supply Vertical Submersible Sewage Pump High-Efficiency WQ/QW Pumps Supplier

NewsJun.10,2025

-

Premium Sewage Ejection System & Pumps Efficient Waste Removal

NewsJun.09,2025

-

Premium Wholesale Slurry Pump Impellers Durable & Efficient Slurry Handling

NewsJun.09,2025

-

Top Sewage Pump Companies Durable Industrial Solutions for Efficiency

NewsJun.09,2025

-

Heavy Duty Slurry Pumps - OEM High Performance & Bulk Wholesale

NewsJun.09,2025