galego

- africano

- albanés

- amárico

- árabe

- armenio

- azerbaiyano

- vasco

- bielorruso

- bengalí

- bosníaco

- búlgaro

- catalán

- Cebuano

- corso

- croata

- checo

- danés

- holandés

- inglés

- Esperanto

- Estonio

- finés

- francés

- frisona

- galego

- xeorxiano

- alemán

- grego

- Gujarati

- crioulo haitiano

- hausa

- hawaiano

- hebreo

- non

- Miao

- húngaro

- islandés

- igbo

- indonesio

- irlandesa

- italiano

- xaponés

- xavanés

- Kannada

- casco

- Khmer

- Ruandés

- coreano

- kurdo

- Kirguises

- TB

- latín

- letón

- lituano

- luxemburgués

- macedonio

- Malgashi

- malaio

- Malayalam

- maltés

- maorí

- Marathi

- mongol

- Myanmar

- nepalí

- noruegués

- noruegués

- occitano

- Pashto

- persa

- polaco

- portugués

- Punjabi

- romanés

- ruso

- samoano

- Gaélico escocés

- serbio

- inglés

- Shona

- Sindhi

- cingalés

- eslovaco

- esloveno

- somalí

- español

- sundanés

- suahili

- sueco

- Tagalo

- taxico

- Tamil

- tártaro

- Telugu

- tailandés

- turco

- turcomano

- ucraíno

- Urdú

- uigur

- uzbeco

- vietnamita

- galés

- Axuda

- yiddish

- ioruba

- Zulú

Teléfono: +86 13120555503

Correo electrónico: frank@cypump.com

Xuñ . 20, 2025 10:22 Volver á lista

Chemical Pump Technology

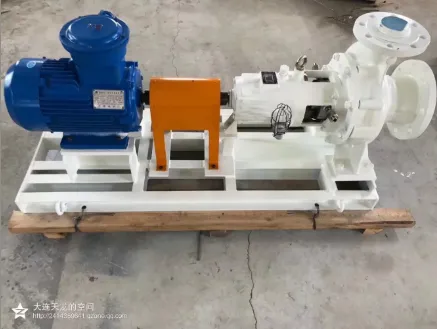

In industries ranging from water treatment and agriculture to petrochemical and pharmaceuticals, the chemical pump plays a crucial role in handling, transferring, and dosing aggressive or hazardous fluids. These specialized pumps are engineered to manage chemicals of all kinds—corrosive acids, volatile solvents, caustic bases, and more—safely and efficiently. Without chemical pumps, industrial processes would face frequent hazards, breakdowns, and environmental contamination.

Unlike standard fluid pumps, chemical pumps are built with corrosion-resistant materials such as PTFE, PVDF, polypropylene, and stainless steel. These materials ensure that even highly reactive or abrasive liquids can be moved without degrading pump components or compromising the safety of operations. Many are also designed to be leak-proof, utilizing magnetic drives or seal-less designs to prevent hazardous fumes or spills.

Depending on the application, chemical pumps come in multiple styles: centrifugal, diaphragm, peristaltic, gear, and piston types. For general fluid transfer, centrifugal chemical pumps are widely used due to their continuous flow capabilities and mechanical simplicity. Diaphragm pumps are often preferred in metering or dosing applications, especially where precision is essential.

Modern chemical pump systems are also integrating smart features like flow control, pressure sensors, and automatic shut-offs to improve process accuracy, reduce chemical waste, and enhance worker safety. In environments where contamination or leaks could result in regulatory fines or equipment failure, a reliable chemical pump is not just a tool—it’s a line of defense.

Chemical Injection Pump Solutions for Precise Dosing

Precision is paramount when it comes to dosing chemicals into a fluid stream, and that's where the chemical injection pump excels. Whether used in agriculture to dose fertilizers, in oil and gas operations for corrosion inhibitors, or in manufacturing to introduce catalysts, this pump type ensures the exact quantity of chemical is delivered at the right pressure and interval.

A chemical injection pump typically delivers low-flow, high-pressure outputs. It is capable of maintaining extremely accurate dosing even under variable system pressure conditions. That accuracy reduces chemical overuse, which saves money and minimizes environmental impact. These pumps are a common feature in systems that require real-time chemical balancing.

In terms of mechanism, injection pumps may use diaphragm, piston, or plunger technology to achieve their dosing precision. The choice depends on the viscosity, reactivity, and flow rate of the fluid. Diaphragm injection pumps are often used for low to medium flow, while piston-style pumps handle high-pressure applications.

In offshore oil rigs and gas pipelines, chemical injection pumps are often driven by pneumatic or hydraulic systems due to the explosion risk associated with electrical motors. These systems are typically housed in stainless steel enclosures and are built to operate 24/7 in the harshest environments.

What makes the chemical injection pump especially valuable is its ability to automate fluid metering. Integration with control systems allows operators to manage and adjust dosing remotely based on sensor input or programmable parameters. This ensures safe, efficient, and reliable chemical treatment with minimal human intervention.

Chemical Feed Pumps Water Treatment Facilities Trust

Clean water is essential to life, and maintaining it requires meticulous chemical treatment—whether in municipal plants, industrial wastewater systems, or rural drinking water supplies. Chemical feed pumps water treatment systems rely on are specially designed to deliver chemicals like chlorine, fluoride, coagulants, and pH balancers with utmost accuracy and consistency.

These pumps are usually positive displacement diaphragm pumps, which offer outstanding repeatability and can maintain steady flow despite changes in pressure or fluid viscosity. Many chemical feed pumps feature adjustable stroke lengths and speeds, allowing for fine-tuned dosing based on real-time water quality readings. This is crucial when conditions fluctuate due to temperature changes, inflow rate, or contamination events.

Safety is paramount in chemical feed pumps water treatment facilities. Pumps are often paired with safety features such as leak detectors, back-pressure valves, and anti-siphon mechanisms to avoid dangerous backflow or unintentional chemical discharge. Because these pumps often operate continuously, durability is key. Corrosion-resistant materials and easy maintenance access help ensure reliable performance over long periods.

In addition to handling treatment chemicals, these pumps are used in pre-treatment processes to protect RO membranes and ion exchange systems from scaling or biological fouling. They're also integral to disinfection processes in drinking water production, where the precise addition of chlorine or chlorine dioxide is essential.

With increasing regulatory pressure on water quality and chemical usage, modern chemical feed pumps are being integrated with SCADA systems and IoT platforms to enable real-time data monitoring and remote troubleshooting. These smart systems allow operators to track dosing rates, receive fault alerts, and prevent system failures before they occur.

Choosing the Right Chemical Pump for Your Application

Selecting the right chemical pump is critical for achieving optimal performance, minimizing downtime, and maintaining safety in your system. The type of chemical being handled—its corrosiveness, viscosity, and temperature—along with system pressure, flow rate, and environmental factors, all influence pump selection.

For example, if you’re handling sulfuric acid, you'll need a pump built from materials like PTFE or PVDF that can withstand aggressive corrosion. If the chemical is highly viscous, such as a polymer solution, a peristaltic pump might be the best choice due to its ability to move thick fluids without clogging.

The operating environment is another major consideration. In areas where flammable gases are present, a pneumatic or explosion-proof chemical injection pump may be necessary. For outdoor installations exposed to temperature extremes, a heated pump enclosure or freeze-protection system might be required.

The level of control you need is also important. For batch processing, a manual pump might suffice, but for continuous flow operations or sensitive water treatment dosing, a programmable chemical feed pump with feedback control is ideal.

Working with an experienced chemical pump supplier ensures that you receive not only the right pump, but also the correct accessories—like valves, tubing, calibration columns, and pulsation dampeners—to ensure complete system functionality and safety.

Future Trends in Chemical Pump Technology

As industries strive for greater efficiency, sustainability, and automation, the future of chemical pump technology is bright. Smart pumps with IoT integration are transforming how facilities monitor and control chemical dosing. These pumps are equipped with sensors that track flow rate, pressure, temperature, and even chemical concentration, transmitting data in real time to centralized systems.

Magnetic drive and seal-less pump designs are also gaining traction, especially in chemical injection and hazardous material handling. These technologies eliminate leak points and reduce maintenance needs, enhancing long-term safety and reliability.

In the realm of chemical feed pumps water treatment, there's growing emphasis on energy efficiency and modularity. New models are being designed with lower power consumption, quieter operation, and compact footprints—making them ideal for retrofitting into existing facilities.

Advanced materials like thermoplastics reinforced with carbon fiber, ceramic coatings, and smart elastomers are being developed to improve chemical resistance and extend pump lifespan. These innovations reduce the frequency of replacement and lower the total cost of ownership.

With the growing demand for sustainable, safe, and automated solutions, chemical pumps, chemical injection pumps, and chemical feed pumps water treatment facilities depend on will continue to evolve—meeting the complex needs of a world increasingly reliant on precise fluid control.

FAQs About Chemical Pumps

What is a chemical pump and how does it differ from a regular pump?

A chemical pump is designed specifically to handle aggressive, corrosive, or hazardous fluids. Unlike regular pumps, it is made with chemically resistant materials such as PTFE, PVDF, or stainless steel. It also features sealed or magnetic drive systems to prevent leaks, ensuring safe fluid transfer in sensitive environments.

Where are chemical injection pumps commonly used?

Chemical injection pumps are widely used in oil and gas operations, water treatment, agriculture, and manufacturing. Their primary purpose is to dose precise amounts of chemicals like corrosion inhibitors, disinfectants, or nutrients into a process stream, ensuring optimal chemical balance and operational safety.

Why are chemical feed pumps important in water treatment?

En water treatment, chemical feed pumps play a vital role in ensuring water safety and quality. They accurately dose disinfectants, coagulants, and pH adjusters, helping to meet regulatory standards, prevent system fouling, and protect public health. Their reliability and precision make them essential for municipal and industrial water systems.

How do I choose the right chemical injection pump for my needs?

To choose the right chemical injection pump, you must consider the chemical’s compatibility with pump materials, the desired flow rate and pressure, the system's operating conditions, and the level of dosing precision required. Consulting with a chemical pump expert can help you identify the best configuration for your application.

Are chemical pumps safe for use in explosive environments?

Yes, many chemical pumps, especially chemical injection pumps, are designed with safety features for explosive environments. Pneumatic or hydraulically driven models are often used in such cases, and pumps can be housed in explosion-proof enclosures or fitted with spark-resistant components to meet industry safety standards.

-

Pipeline Pump Excellence: Efficient, Quiet, Reliable Flow

NovasNov.17,2025

-

Horizontal Split Case Pump - Double Suction, High Efficiency

NovasNov.17,2025

-

Vertical Slurry Pumps | Heavy-Duty, Abrasion-Resistant

NovasNov.17,2025

-

Septic Tank Pumps: Durable, Energy-Efficient, Submersible

NovasNov.17,2025

-

Axial Flow Pump – High-Flow, Low-Head Efficiency, Durable

NovasNov.17,2025

-

ZJW Abrasion Resistant Feed Slurry Pump | Durable, Efficient

NovasNov.11,2025