Estonian

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

okt. . 16, 2024 04:04 Back to list

Efficient Horizontal End Suction Pump for Chemical Applications and Fluid Transfer

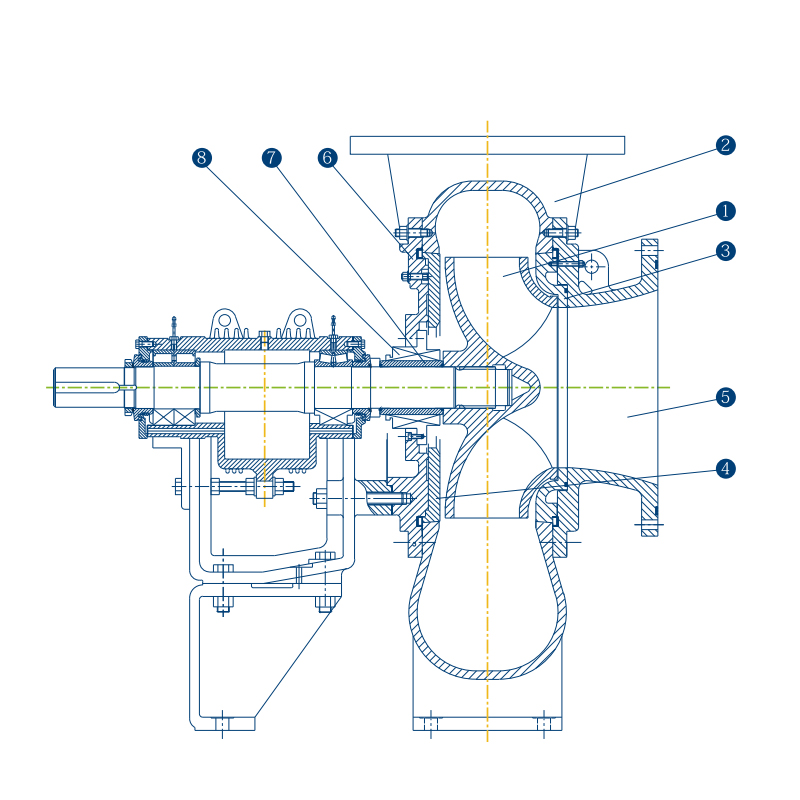

Understanding the Good Horizontal End Suction Chemical Pump

Pumps play an essential role in numerous industrial processes, particularly in the transport of liquids across various applications. Among the myriad of pump designs available, the good horizontal end suction chemical pump stands out due to its efficient and reliable operation in handling corrosive and viscous fluids. This article delves into the features, benefits, applications, and maintenance considerations of these pumps, helping industries make informed decisions about their fluid transport needs.

Design Features

The horizontal end suction chemical pump is characterized by its simple yet effective design. It typically includes a horizontal configuration, which allows for easy installation and maintenance. The pump’s construction usually features a robust casing designed to withstand the harsh chemical environments often encountered in industrial settings. The end suction design ensures that fluid enters the pump at the end of the impeller, enabling efficient flow management and reduced turbulence, which is crucial for sensitive or viscous materials.

These pumps are often equipped with various impeller types—including open, semi-open, and closed configurations—allowing operators to select the most appropriate impeller for their specific fluid properties. The choice of materials is also critical; common options include stainless steel, duplex stainless steel, and various corrosion-resistant alloys, ensuring longevity and reliability in abrasive or corrosive conditions.

Operating Efficiency

One of the standout features of horizontal end suction chemical pumps is their energy efficiency. With precision-engineered components, these pumps can achieve high levels of performance with minimal energy consumption. The pump's design allows for a smooth flow of fluid, reducing the energy required for transportation and minimizing operational costs. Additionally, the efficient design helps in reducing wear and tear on the pump components, leading to lower maintenance demands over time.

Benefits

1. Versatility Good horizontal end suction chemical pumps can handle a wide range of fluids, including corrosive chemicals, slurries, and viscous liquids. This versatility makes them suitable for various industries, from chemical processing to food and beverage production.

good horizontal end suction chemical pump

2. Ease of Maintenance With their straightforward design, these pumps are generally easier to disassemble and maintain compared to more complex systems. This ease of access allows for quicker repairs and reduces downtime, which is vital in maintaining the efficiency of production processes.

3. Durability Built to withstand demanding environments, these pumps exhibit remarkable durability. The use of high-quality materials and thoughtful engineering contributes to their resilience, ensuring they remain operational for extended periods, reducing the need for frequent replacements.

4. Cost-Effectiveness While the initial investment for a high-quality horizontal end suction pump may be significant, the long-term savings in energy costs, reduced maintenance, and improved operational efficiency make them a cost-effective choice for many businesses.

Applications

The versatility and reliability of horizontal end suction chemical pumps make them suitable for various applications across different industries

- Chemical Processing Essential for transporting aggressive chemicals during manufacturing processes. - Water Treatment Used in both municipal and industrial water treatment facilities for chemical dosing and raw water transportation. - Food and Beverage Handles various food-grade liquids, supporting processes from ingredient transport to packaging. - Pharmaceuticals Ensures the safe transfer of sensitive substances in drug production and distribution.

Maintenance Considerations

While horizontal end suction chemical pumps are designed for durability, regular maintenance is crucial for ensuring their longevity and efficient operation. Operators should implement a routine inspection schedule focusing on components such as seals, bearings, and the impeller. Keeping an eye on vibration levels, noise, and fluid leaks can help identify potential issues before they escalate into significant problems.

In conclusion, good horizontal end suction chemical pumps are a vital component of many industrial processes – celebrated for their efficiency, versatility, and durability. By understanding their design, benefits, applications, and maintenance requirements, businesses can make strategic investments that enhance productivity and sustainability in their operations.

-

ISG Series Pipeline Pump - Chi Yuan Pumps | Energy Efficiency&Compact Design

NewsAug.03,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Low Noise, Durable

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump- Chi Yuan Pumps Co., LTD.|High Efficiency&Compact Design

NewsAug.02,2025

-

Heavy-Duty Mining Sludge Pumps - Wear-Resistant Slurry Handling

NewsAug.02,2025

-

Horizontal Split Case Pump with GPT-4 Turbo | High Efficiency

NewsAug.01,2025