Spanish

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Ago . 01, 2024 01:42 Back to list

Innovative Solutions for Efficient Transportation of Pneumatic Slurry Through Advanced Pump Technology

The Pneumatic Slurry Pump An Innovative Solution for Challenging Applications

In the world of fluid transportation, particularly in industrial applications, the demand for efficient and reliable pumps has never been greater. Among the many types of pumps available, the pneumatic slurry pump stands out as an innovative solution designed to handle the difficult task of moving slurry—a mixture of solids and fluids, typically found in industries such as mining, construction, and wastewater treatment.

What is a Pneumatic Slurry Pump?

A pneumatic slurry pump is a type of pump that operates using compressed air to move slurry materials. Unlike traditional pumps that rely on electric motors or mechanical drives, pneumatic pumps utilize air pressure to create a vacuum that draws slurry into the pump chamber. The design of these pumps allows them to handle thick, viscous mixtures that often contain abrasive solids, making them suitable for applications where conventional pumps may struggle or fail.

Key Advantages of Pneumatic Slurry Pumps

1. Versatility Pneumatic slurry pumps can effectively transport a wide variety of materials, including coarse and fine particles, as well as highly viscous fluids. This versatility makes them ideal for applications in industries such as mining, where they can manage ore slurries, or in wastewater treatment, where they handle sludge.

2. Corrosion Resistance Many pneumatic slurry pumps are constructed from durable materials such as stainless steel, rubber, or specialized polymers. This makes them resistant to corrosion caused by abrasive particles and chemical exposure, extending their operational lifespan and reducing maintenance costs.

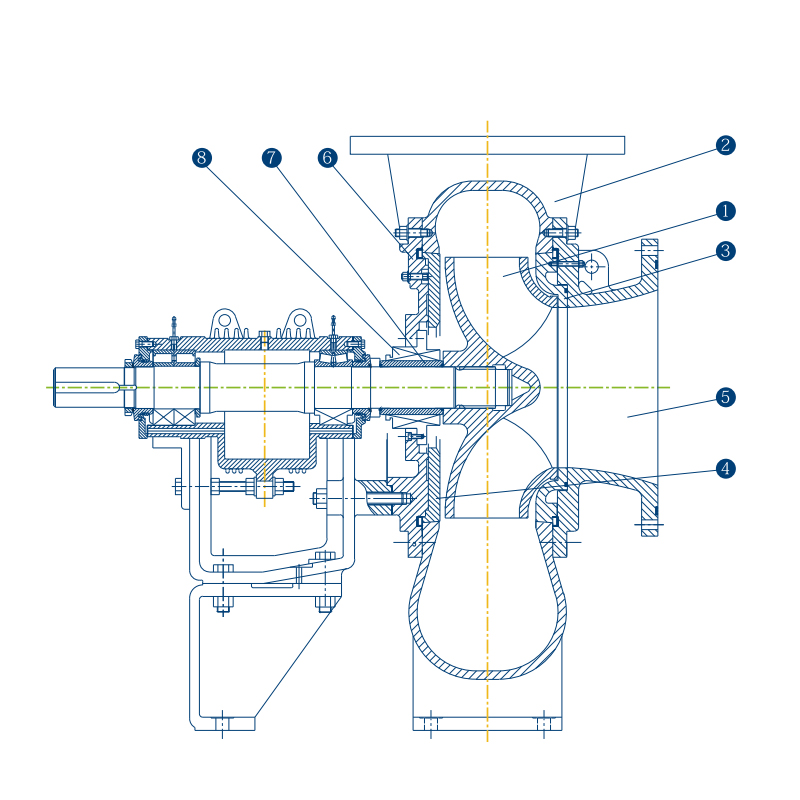

pneumatic slurry pump

3. Reduced Energy Consumption By utilizing compressed air, pneumatic slurry pumps can be more energy-efficient than their electric counterparts. They can be powered by air compressors, which may already be part of an industrial facility's infrastructure, further reducing the need for additional energy sources.

4. Simpler Operation and Maintenance Pneumatic pumps generally have fewer moving parts and do not require complex electrical connections. This simplicity means that they can be easier to operate and maintain, resulting in less downtime and lower labor costs.

5. Environmentally Friendly Pneumatic pumps operate quietly and produce minimal emissions since they rely on air rather than fossil fuels or electricity from conventional power plants. This makes them a more environmentally friendly option for transporting slurry materials in sensitive locations.

Applications of Pneumatic Slurry Pumps

The applications for pneumatic slurry pumps are vast. In mining operations, they are used to transport mineral slurries from extraction sites to processing plants. In construction, they can efficiently pump concrete or other thick materials needed for large-scale projects. Additionally, in the field of wastewater management, these pumps move sludge and other by-products through treatment facilities, ensuring effective waste disposal and environmental protection.

Conclusion

The pneumatic slurry pump represents a significant advancement in the field of fluid handling technology. Its versatility, energy efficiency, and durability make it an optimal choice for industries dealing with challenging slurry materials. As industries continue to evolve and demand more innovative solutions, pneumatic slurry pumps are likely to play an increasingly important role in ensuring the efficient and safe transportation of complex mixtures. With their ability to streamline operations and reduce environmental impact, pneumatic slurry pumps are more than just tools—they are essential components for the future of industrial fluid transport.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Low Noise, Durable

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump- Chi Yuan Pumps Co., LTD.|High Efficiency&Compact Design

NewsAug.02,2025

-

Heavy-Duty Mining Sludge Pumps - Wear-Resistant Slurry Handling

NewsAug.02,2025

-

Horizontal Split Case Pump with GPT-4 Turbo | High Efficiency

NewsAug.01,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

NewsAug.01,2025