Cebuano

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Nov . 09, 2024 14:53 Back to list

Efficient Water Pump Solutions for Chemical Pipeline Applications and Industrial Use

The Importance of Using Good Chemical Pipeline Water Pumps

In the modern industrial landscape, the efficient handling of chemicals is critical for a variety of sectors, including manufacturing, agriculture, and water treatment. One of the pivotal components in these industries is the chemical pipeline water pump. A good chemical pipeline water pump not only ensures the effective transport of liquids but also plays a significant role in maintaining safety and environmental standards.

Understanding the Functionality of Chemical Pipeline Water Pumps

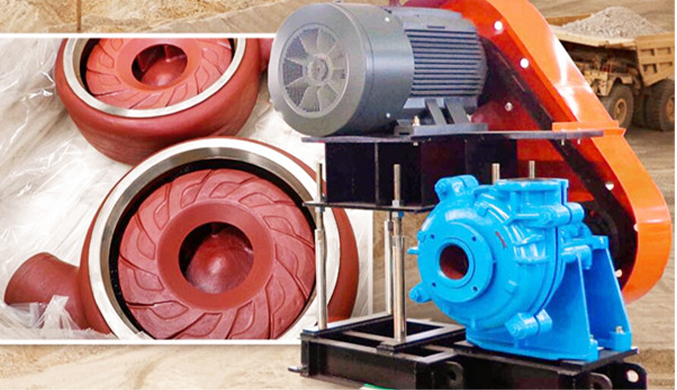

A chemical pipeline water pump is specifically designed to move chemicals and other hazardous materials through a network of pipelines. These pumps are engineered to handle a wide range of fluids, from corrosive acids to viscous slurries. The design and material selection are crucial, as they need to withstand the aggressive nature of many chemicals, which can cause wear and tear on standard pumping systems.

Typically, a good chemical pipeline water pump will utilize materials such as stainless steel, polypropylene, or other resistant composites to ensure longevity and reliability. Furthermore, these pumps are designed to minimize the risk of leaks, which can lead to unsafe working conditions and environmental hazards.

The Role of Chemical Pumps in Industry

In industries such as pharmaceuticals and food processing, the ability to transport chemicals securely and efficiently is non-negotiable. These sectors often face strict regulatory standards regarding the handling of chemicals to ensure safety for both workers and end-users. By using high-quality chemical pipeline water pumps, companies can maintain compliance with these regulations while safeguarding their operations against potential failures.

Moreover, industries that utilize chemical pipeline pumps often deal with complex systems involving multiple stages of processing. A good pump can help streamline these processes, reducing downtime and increasing productivity. For instance, in a water treatment facility, the ability to move chemicals like chlorine or coagulants efficiently is vital to ensure that the water is treated properly before distribution.

Safety Considerations

good chemical pipeline water pump

Safety is a primary concern when dealing with chemicals. A good chemical pipeline water pump incorporates various safety features to mitigate risks associated with chemical spills, leaks, or equipment failure. Features such as automatic shut-off systems, pressure relief valves, and advanced monitoring technology allow operators to manage the pumping process more effectively and respond swiftly in case of abnormalities.

Additionally, regular maintenance is crucial for ensuring that chemical pipeline water pumps operate safely and efficiently. Scheduled inspections and timely repairs can prevent unexpected breakdowns that could lead to potentially dangerous situations. Investing in high-quality pumps often translates into lower maintenance costs over time, making them a financially sound choice for industries relying on chemical transportation.

Environmental Impact

Environmental stewardship is becoming increasingly vital for all industries, and the efficient use of chemical pipeline water pumps can significantly reduce environmental footprints. Good pumps that minimize leaks and ensure precise delivery of chemicals can help limit waste and prevent contamination of surrounding areas.

Moreover, the energy efficiency of a chemical pump can also have a substantial impact on environmental sustainability. Energy-efficient pumps reduce electricity consumption, which not only lowers operational costs but also contributes to a reduction in greenhouse gas emissions.

Conclusion

In conclusion, the selection of a good chemical pipeline water pump is a critical decision for any industry that engages with hazardous materials. Beyond ensuring efficient transportation, these pumps play a pivotal role in safety, compliance, and environmental responsibility. By investing in high-quality chemical pumps, companies can protect their employees, meet regulatory standards, and contribute positively to their communities.

As the industrial landscape continues to evolve, the need for reliable and efficient chemical transportation solutions will only grow. Thus, prioritizing the selection and maintenance of good chemical pipeline water pumps is essential for achieving operational efficiency and sustainability in today’s competitive market.

-

High-Performance Air Pumps for Sand & Gravel | Efficient Transport

NewsAug.03,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Energy Efficiency, Corrosion Resistance

NewsAug.03,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | Energy Efficiency&Compact Design

NewsAug.03,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Low Noise, Durable

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | High Efficiency, Low Noise

NewsAug.02,2025

-

ISG Series Vertical Pipeline Pump- Chi Yuan Pumps Co., LTD.|High Efficiency&Compact Design

NewsAug.02,2025