Cebuano

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

Dis . 23, 2024 09:50 Back to list

froth slurry pump

Understanding the Importance of Froth Slurry Pumps in Industrial Applications

Froth slurry pumps are critical components in various industrial processes, particularly in the mining, mineral processing, and wastewater treatment sectors. These pumps are specially designed to handle the unique challenges posed by slurries that contain frothy elements, such as air bubbles and finely suspended particles. In this article, we will explore the operational principles, applications, and challenges associated with froth slurry pumps, highlighting their significance in modern industry.

What is Froth Slurry?

Froth slurry consists of a mixture of solids, liquids, and air that forms a frothy mass during processes such as flotation in mineral processing. The presence of froth can complicate the transport of the slurry, as the air bubbles can significantly affect the viscosity and density of the mixture. Handling this type of slurry requires specialized pumping solutions that can effectively manage both the solid content and the frothy nature of the mixture.

Operational Principles of Froth Slurry Pumps

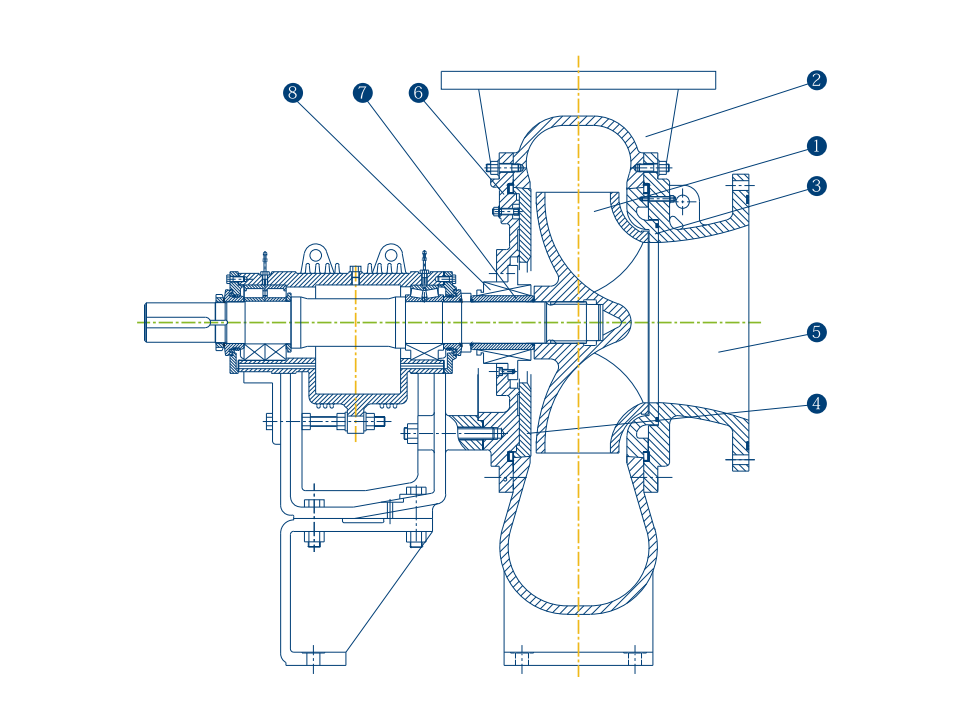

Froth slurry pumps are engineered to efficiently transport slurries while minimizing the issues caused by froth formation. These pumps typically feature a robust design that can handle the abrasive nature of slurries and reduce the risk of blockages and cavitation. Key design elements of froth slurry pumps include

1. Wide Inlet and Discharge Openings Ensuring that the pump is capable of handling larger volumes of frothy material without clogging.

2. High-Performance Impellers Designed to create the necessary pressure and flow rates to move both solids and liquids effectively. The impeller geometry is crucial for maintaining a balance between velocity and the capacity to handle air.

3. Adjustable Volumes Many froth slurry pumps offer adjustable flow volumes and pressure, allowing operators to optimize performance based on the specific characteristics of the slurry being processed.

4. Durable Materials Constructed from wear-resistant materials to withstand abrasive particles and corrosive environments common in mining and mineral processing applications.

Applications of Froth Slurry Pumps

Froth slurry pumps are integral to numerous industrial applications

froth slurry pump

- Mining and Ore Processing In these sectors, froth flotation is used to separate valuable minerals from ore. Froth slurry pumps are essential for transporting the slurry to and from flotation cells, ensuring efficient separation and recovery of minerals.

- Wastewater Treatment Froth pumps aid in the movement of sludge and slurry in treatment facilities, facilitating the efficient separation of solids from liquids.

- Chemical Processing In scenarios that require the mixing of chemicals with solid particulate matter, froth slurry pumps provide a reliable means to move these mixtures without compromising the integrity of the materials.

- Pulp and Paper Industry These pumps are used to transport wood chips and pulps, maintaining process efficiency where froth formation may occur.

Challenges Faced by Froth Slurry Pumps

Despite their advantages, froth slurry pumps encounter several challenges

- Cavitation The presence of air bubbles can lead to cavitation, which causes damage to the pump components and reduces efficiency. Proper design and operational adjustments are essential to mitigate cavitation risks.

- Viscosity Variations Fluctuations in the density and viscosity of the slurry, due to changes in composition, can affect pump performance. Continuous monitoring and adjustment may be required.

- Maintenance Froth slurry pumps require regular maintenance to ensure optimal performance and to address wear and tear from abrasive materials.

Conclusion

Froth slurry pumps play an indispensable role in various industrial processes that involve transporting slurries with frothy characteristics. Their specialized design and operational capabilities allow them to effectively manage the complexities of frothy slurries, contributing to efficiency and productivity in mining, wastewater treatment, and other sectors. However, understanding the associated challenges is essential for optimizing performance and ensuring the longevity of these vital pumping systems. As industries continue to evolve, the importance of reliable froth slurry pumps remains paramount in promoting efficient and sustainable operations.

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|High Efficiency, Energy Saving, Low Noise

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump- Chi Yuan Pumps|High Efficiency&Low Noise

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump-Chi Yuan Pumps Co., LTD.|High Efficiency&Energy Conservation

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|Advanced Hydraulic Design&Energy-Efficient Solutions

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.

NewsJul.30,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps Co., LTD.|energy-efficient fluid handling&industrial durability

NewsJul.30,2025