Arabic

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Telephone: +86 13120555503

Email: frank@cypump.com

نوفمبر . 23, 2024 00:37 Back to list

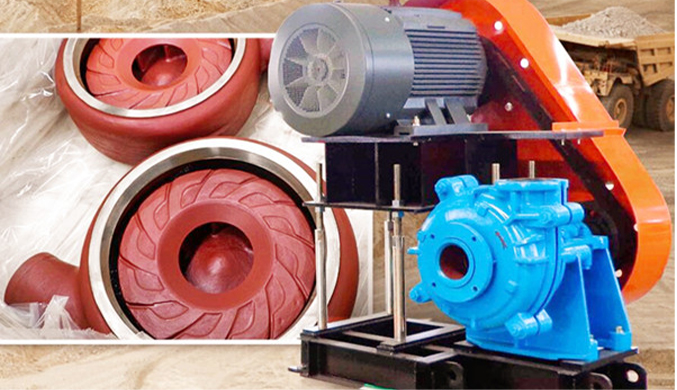

slurry pump metal lined parts

Understanding Slurry Pump Metal Lined Parts

Slurry pumps play a crucial role in industries that require the transportation of abrasive or corrosive materials, such as mining, construction, and wastewater management. These pumps are designed to handle slurry—a mixture of liquid and solid particles—efficiently and effectively. One of the essential components of slurry pumps is their metal-lined parts, which provide durability and resistance to wear.

Understanding Slurry Pump Metal Lined Parts

One of the primary benefits of using metal-lined parts in slurry pumps is their wear resistance. Slurries often contain sharp, abrasive particles that can quickly erode traditional materials. Metal linings act as a protective barrier, ensuring that the pump maintains its integrity over time. This resistance to abrasion is particularly important in industries like mining, where the movement of gravel, sand, or mineral-laden slurry can lead to frequent breakdowns if less durable materials are utilized.

slurry pump metal lined parts

In addition to wear resistance, metal-lined parts provide excellent performance under varying pressures and temperatures. Slurry pumps are often subjected to extreme operating conditions, including high pressure and fluctuating temperatures. The robust nature of metal linings ensures that these pumps can operate efficiently, minimizing the risk of failure and avoiding costly downtimes.

Another significant advantage of metal liners is their ease of maintenance. When wear does occur, it is often localized, meaning that only specific components may require replacement. This targeted maintenance approach can lead to reduced operational costs. Furthermore, many slurry pumps are designed with modular systems, allowing for quick and efficient replacement of worn metal parts without the need for complete pump disassembly.

Furthermore, the use of metal-lined parts can contribute to the overall energy efficiency of slurry pumps. With enhanced durability and performance, these pumps can operate at lower energy costs over time. Improved efficiency not only translates to cost savings but also minimizes the environmental impact associated with excessive energy consumption.

In conclusion, metal-lined parts are vital for the effectiveness and durability of slurry pumps. They provide essential wear resistance, enable high-performance operations under challenging conditions, and facilitate easier maintenance. As industries continue to rely on slurry pumps for critical operations, the importance of quality metal linings will only increase, marking them as a key component in the ongoing quest for efficiency and reliability in industrial processes. Proper selection, maintenance, and management of these components will ensure optimal performance and longevity, safeguarding operations against the demanding nature of slurry transportation.

-

Heavy-Duty Mining Sludge Pumps - Wear-Resistant Slurry Handling

NewsAug.02,2025

-

Horizontal Split Case Pump with GPT-4 Turbo | High Efficiency

NewsAug.01,2025

-

ISG Series Pipeline Pump - Chi Yuan Pumps | High Efficiency, Durable Design

NewsAug.01,2025

-

Advanced Flue Gas Desulfurization Pump with GPT-4 Turbo | Durable & Efficient

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Advanced Hydraulic Design&Durable Construction

NewsJul.31,2025

-

ISG Series Vertical Pipeline Pump - Chi Yuan Pumps | Energy Efficient & Low Noise

NewsJul.31,2025